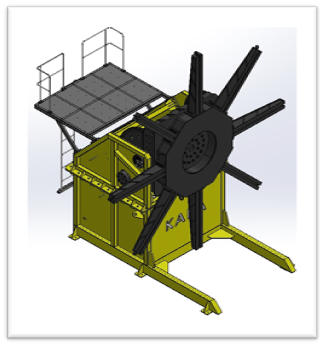

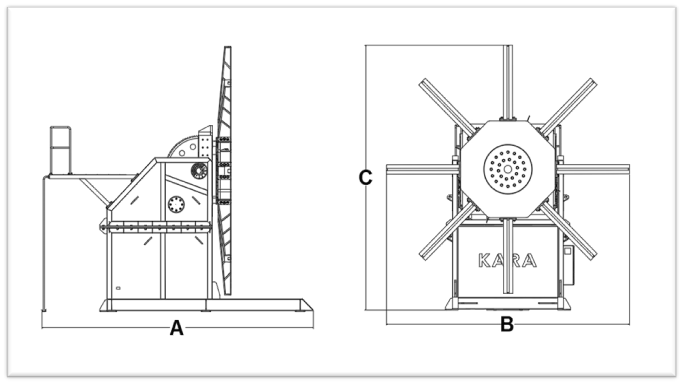

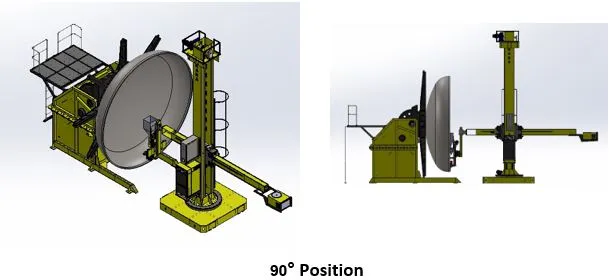

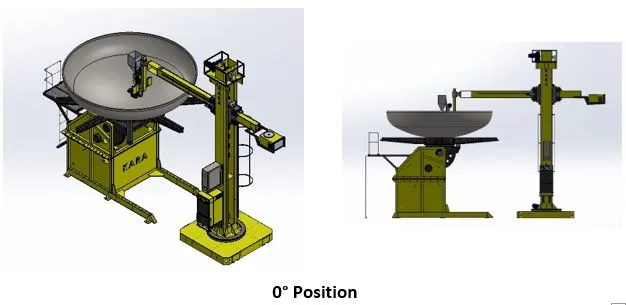

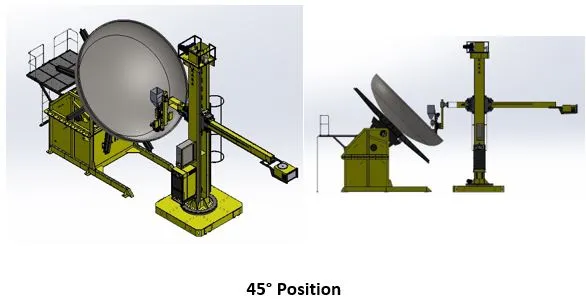

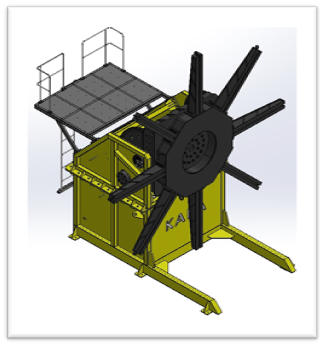

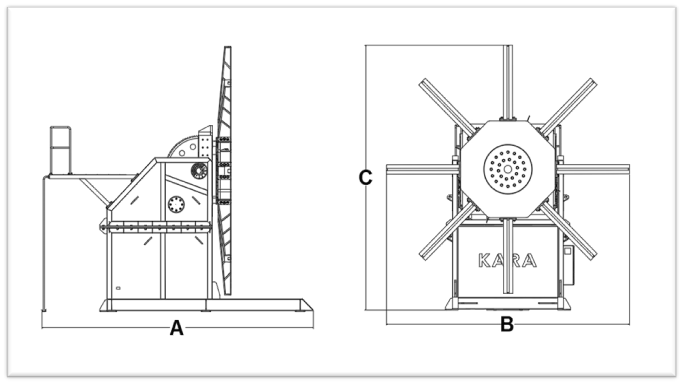

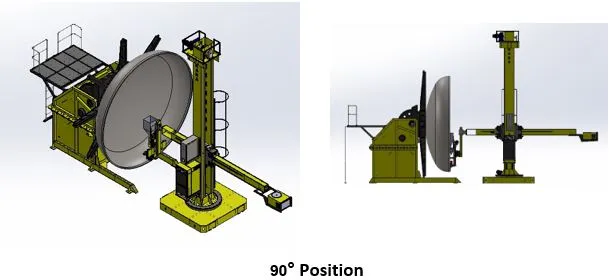

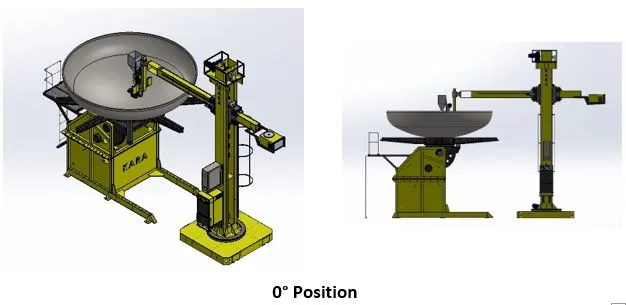

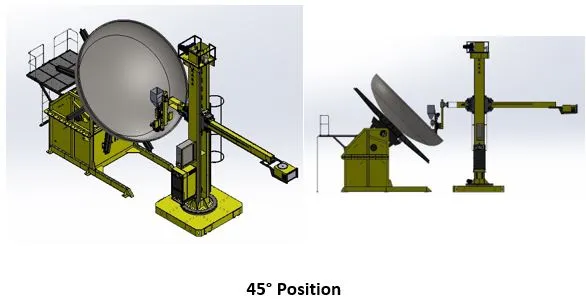

Dish Cladding Machine

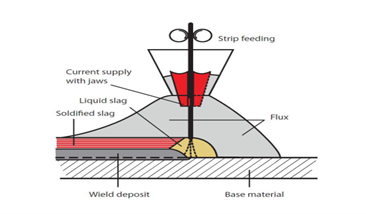

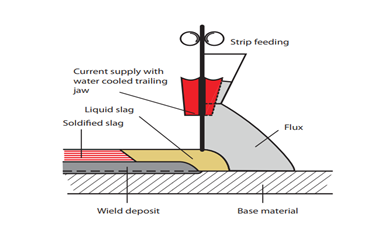

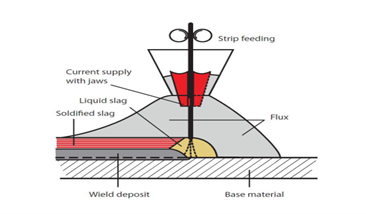

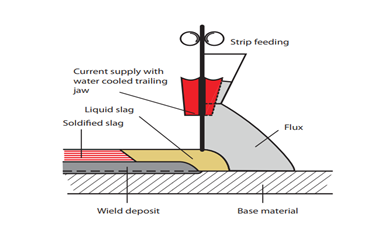

ESW strip claddingElectroslag strip cladding is a development of submerged arc strip cladding which has quickly established itself as a reliable high deposition rate process.

ESW strip cladding relates to the resistance welding processes and is based on the ohmic resistance heating of a molten electrically conductive slag.There is no arc between the strip electrode and the parent material. The heat generated by the molten slag melts the surface of thebasematerial, and the edge of the strip electrode is submerged in the slag and flux.

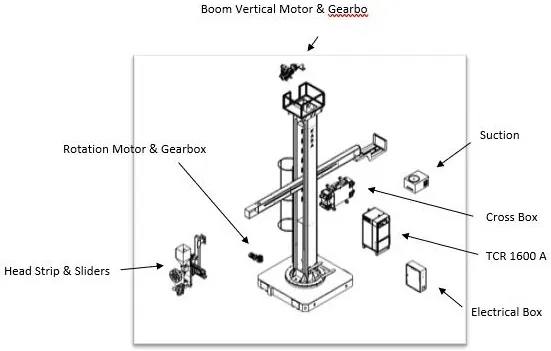

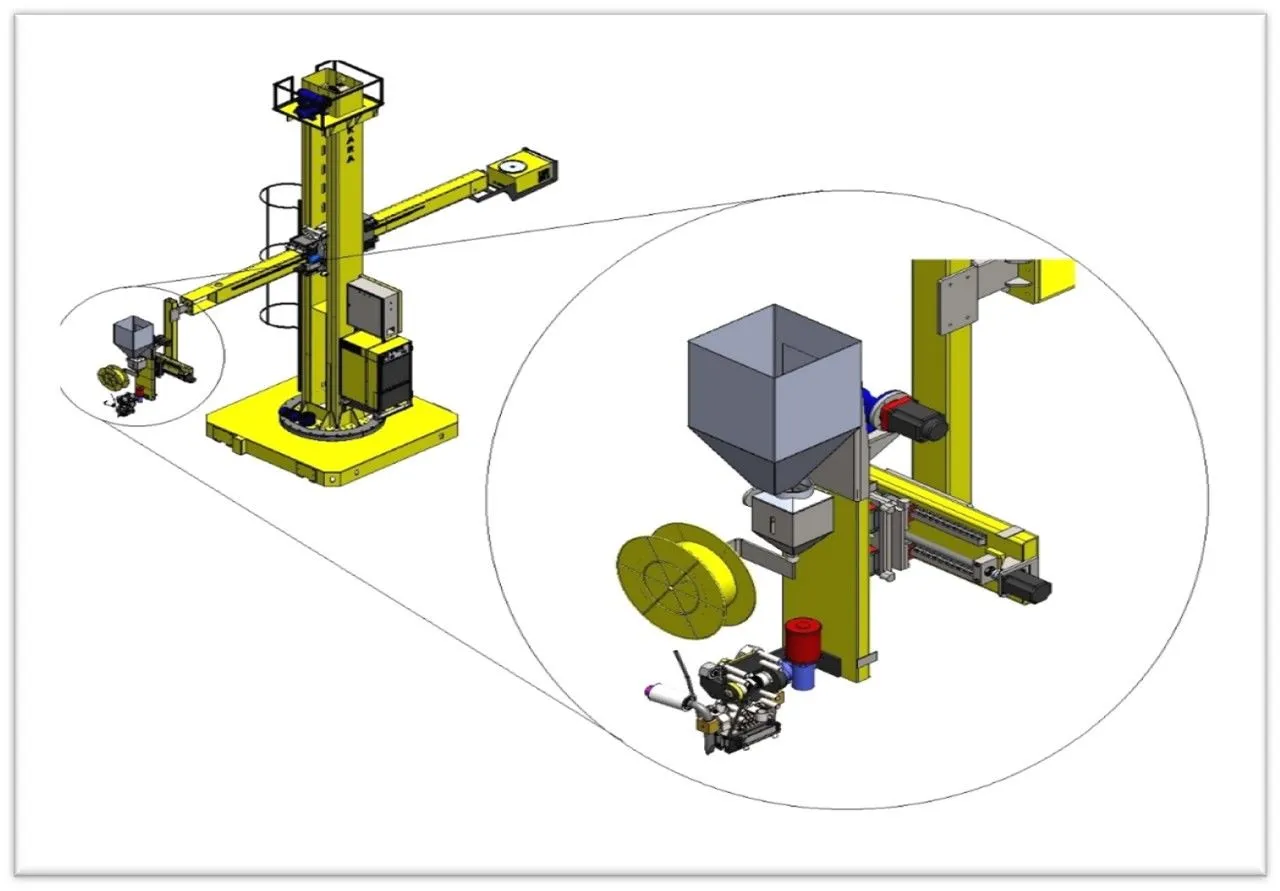

Strip Clad Head

Strip Clad HeadSAW strip cladding

The well-known SAW method has been widely used with strip electrodes sincethe mid-1960s. A strip electrode, normally measuring 60 x 0.5 mm or 90 x 0.5 mm, is used as the (usually positive) electrode and an electric arc is formed between the strip and the workpiece. Flux is used to form a molten slag to protect the weld pool from the atmosphere and helps to form a smooth weld bead surface

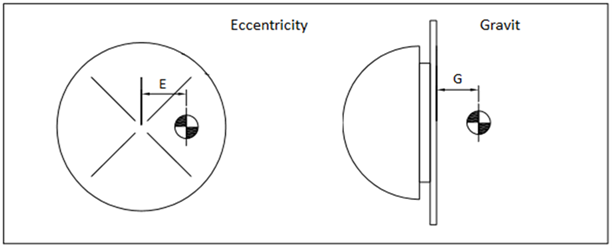

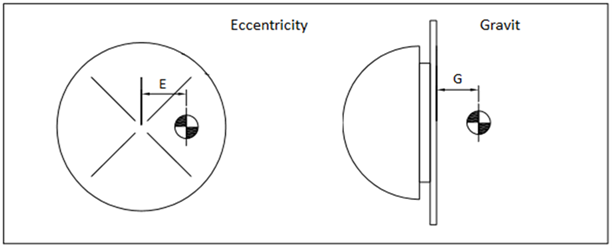

Dish Cladding Machine

Dish Cladding Machine، The penetration achieved with ESW is less than that with for SAW because the molten slag pool is used to melt the strip and some of the parent material. The temperature of the slag pool is about 2300°C, making it necessary to water-cool the contact jaws.

ESW uses higher welding currents than SAW strip cladding so the welding heads used are more heavy duty.

The following shows the features of ESW compared with the strip cladding process.

- Increased deposition rate of 60% to 80%.

- Only half of the dilution (10%-15%) from the base material due to less penetration.

- Lower arc voltage (24-26 V).

- Higher amperage and current density (About 1000-1250 A with strips of 60 mm width , corresponding to 33-42A/mm2).Specially developed Fluxes for high productivity purposes can be welded with amperage in excess of 2000 A which corresponds to a current density about 70 A/mm2 .

- Increased welding speed (50%-200%) , resulting in a higher area coverage in m2 /h.

- Comparable heat input.

- Lower flux consumption (about 0.5 kg/kg strip).

- The solidification rate of the ESW weld metal is lower , aids de-gassing and increases resistance to porosity. Oxides can rise easier out of the molten pool to the

- surface; resulting in a metallurgically cleaner weld metal which is less sensitive to hot cracking and corrosion.

Fluxes for ESW

The ESW-process requires a slag pool with an ohmic resistance behavior. In comparison to SAW cladding the electrical conductance must be higher to avoid arc flash, which is a disturbance of the process .The composition of the welding flux

Influences the conductivity , the solidification range and the viscosity of the molten slag. To increase the cladding speed at corresponding high

welding currents, it is necessary to use fluxes with high electrical conductivity and low viscosity.

Strip Clad Head

Strip Clad Head