Fiber Laser Cutting

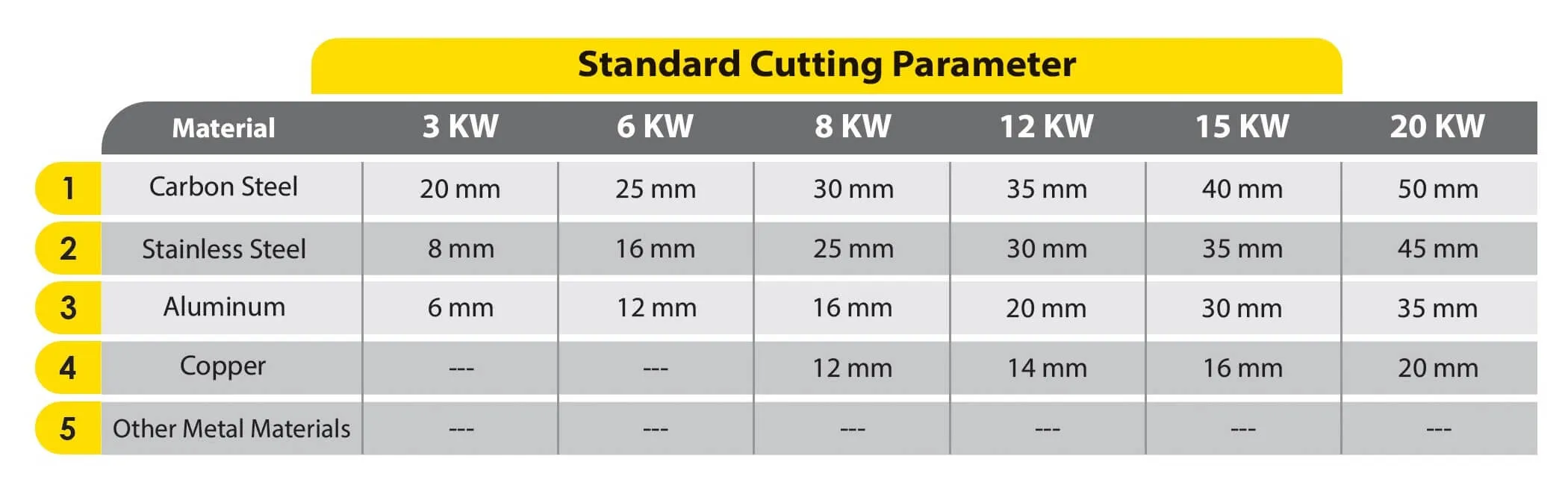

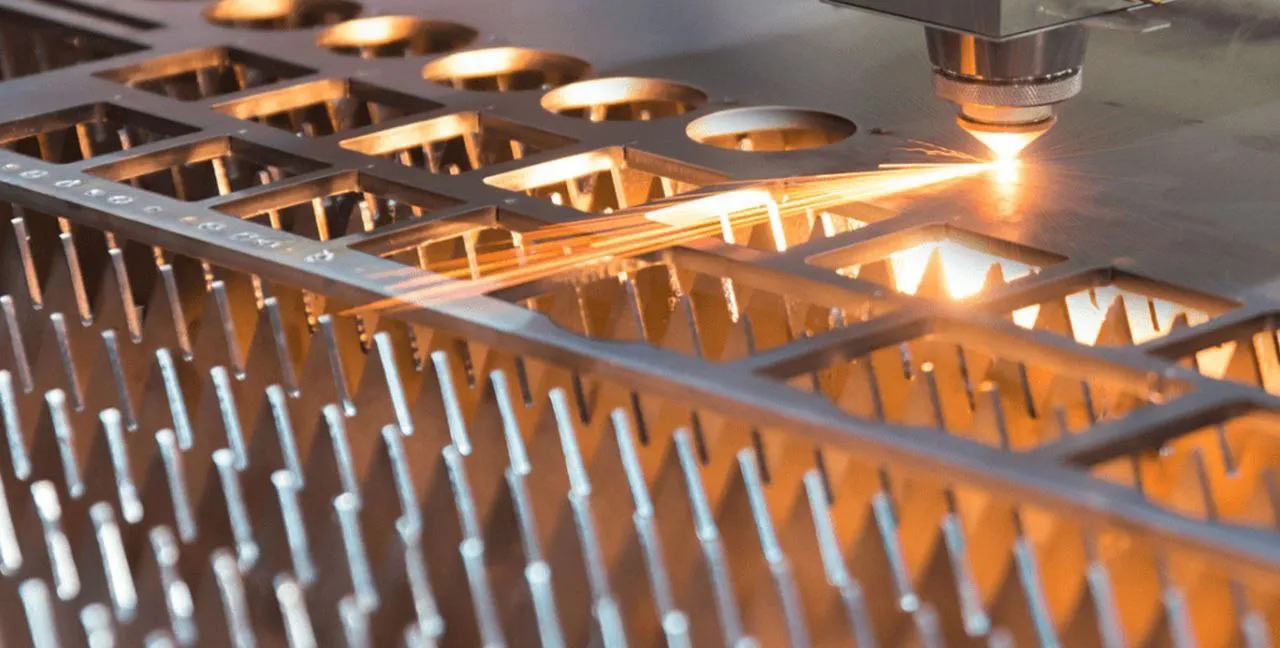

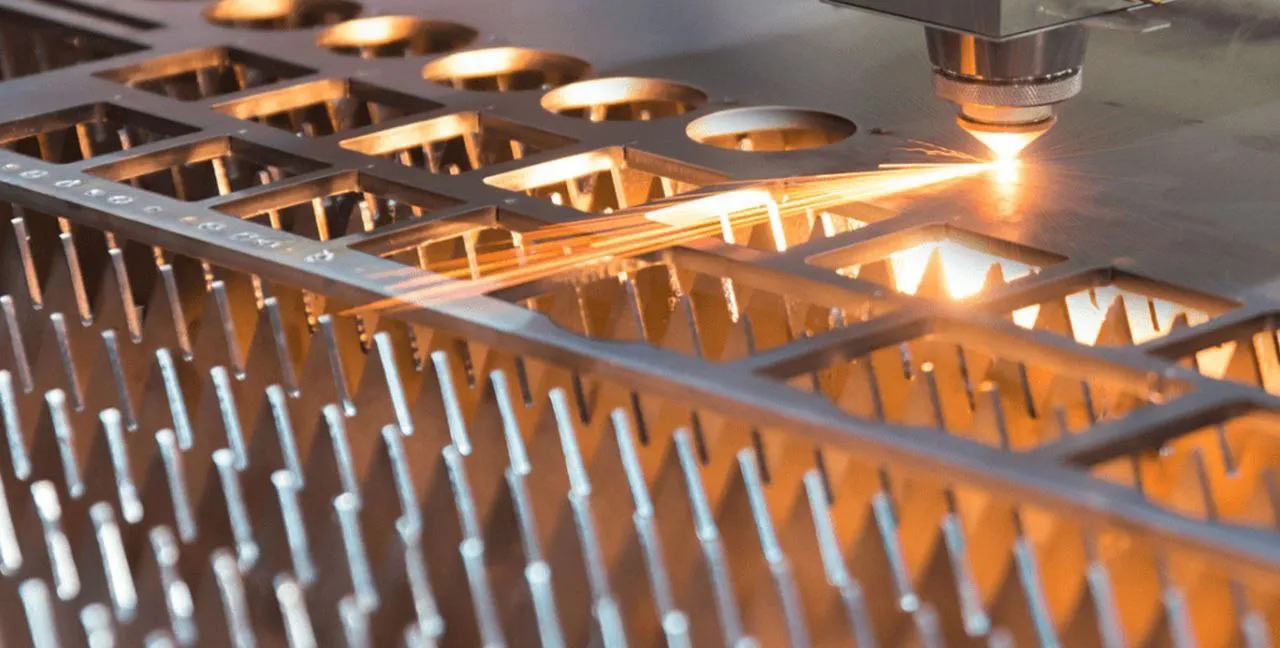

DescriptionIntroductionKara fiber laser cutting machine is exclusively designed for precise and fast cutting of various metal parts. Various materials such as copper, aluminum, stainless steel and structural steel can be cut easily and efficiently with this machine.

Fiber laser cutting consists of several main parts such as the table, laser source, control systems and user interface. This machine does not have a housing around the table and the operator has full access to all parts of the machine and the workpiece.Machine chassis

The Kara laser cutting machine is designed to be robust and stable enough to withstand the weight of the workpiece and unexpected external impacts, maintaining the accuracy and quality of the cut parts.The main chassis specifications are:

- Standard steel frame profile

- Post-welding heat treatment to reduce residual stresses

- One-time machining process after complete assembly and welding operation

- Waste guided into a small under-chassis wagon

- Equipped with dust collection channel

- Special rear box for storing welding equipment

Main features of undercarriage

- Sturdy construction

- Equipped with 4 wheels for moving on uneven paths

- Equipped with a hinged handle for easy movement

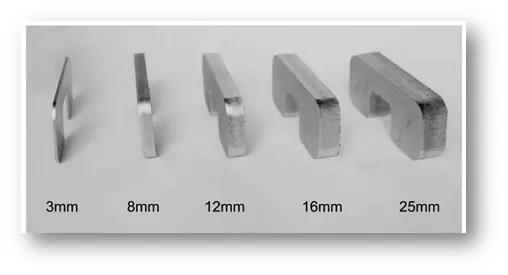

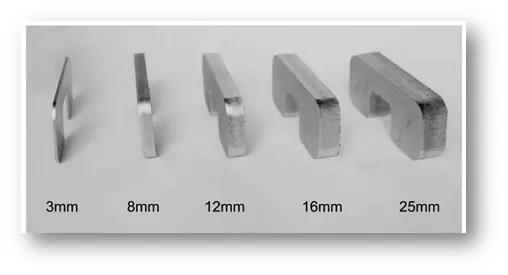

- Strip table for laser cutting machine

- With a durable coil for proper blade storage

- Appropriate distance between blades

- Easy replacement of the strip table set

- Easy replacement of the blades individually

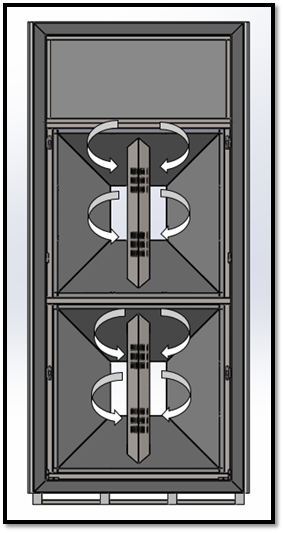

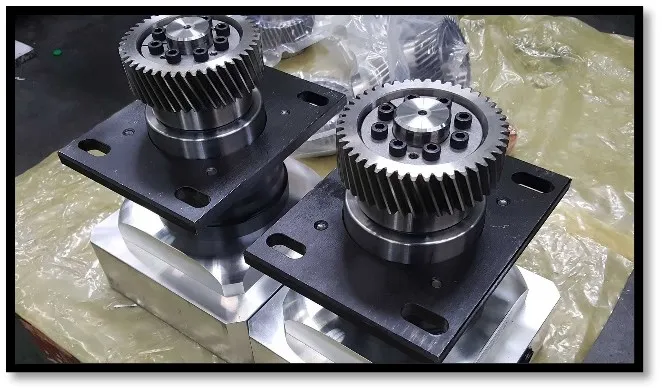

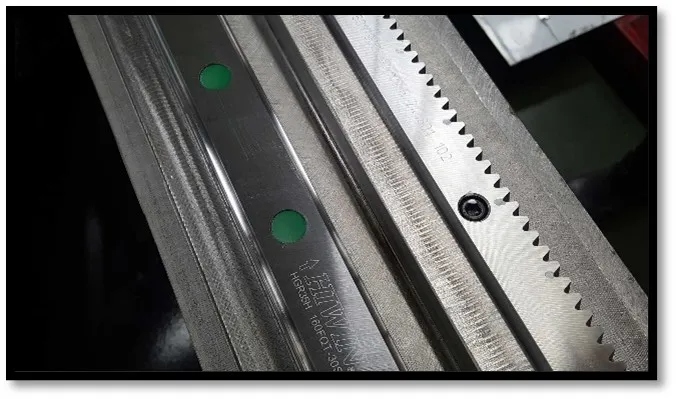

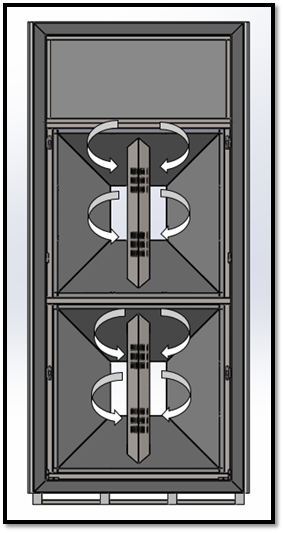

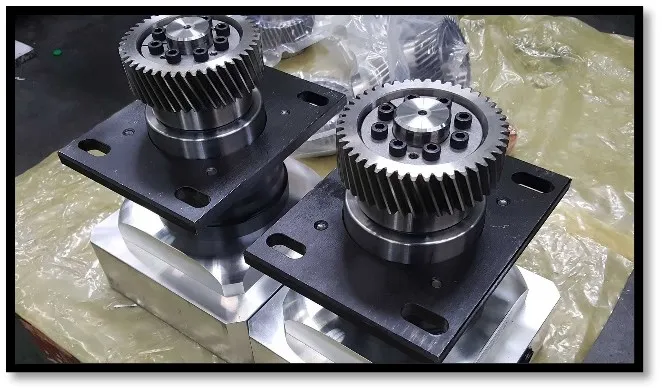

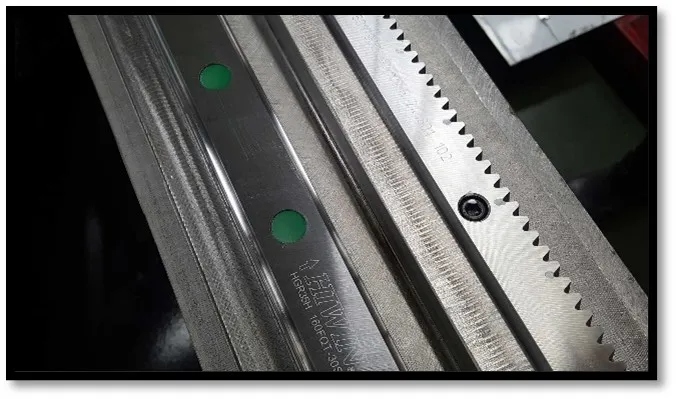

The drive mechanism of this gantry includes a servo motor, a planetary gearbox, and a rack and pinion system (Rack & Pinion) located on both sides of the machine. The low backlash of this drive mechanism allows smooth and precise movement of the gantry along the machine table.

The control system is equipped with IPC technology and offers advanced capabilities for complex cutting operations. In addition to controlling movement along the three main axes, the system can regulate the laser beam power based on sheet thickness, material type, and cutting parameters.

- Aluminum boom

- Rigid and precise frame

- Standard aluminum profile with no residual stress

- Significantly lower weight compared to a steel boom of the same size

- CNC control system

The CNC control system is equipped with industrial-grade hardware and analog switches. The G-code cutting program can be loaded via USB flash drive or Wi-Fi network.The hardware components of this CNC controller are designed to operate reliably in harsh environments where dust and electromagnetic noise are common.

- Monitor stand

- With high-strength structure

- 270-degree rotation of the base

- 360-degree rotation of the monitor and keyboard holder

- Monitor height adjustment

- With wireless mouse and keyboard for easy movement

- Controlled Axes

The CNC controller of the laser cutting machine can control movement along three independent axes. These axes are listed below:

- Longitudinal axis

- Traverse axis

- Height axis (distance between the cutting head and the workpiece)

Laser Cutting Machine Equipment

- Laser power supply

- High electro-optical efficiency

- High-quality laser beam

- High energy density

- Wide range of frequency modulation

- High reliability during long operating periods

- Long lifespan without the need for maintenance

The laser power supply can be customized according to the customer's preference.

- Automatic focus

- Easy replacement of protective lenses

- Compatible with various QBH power supplies

- Use two adjustment screws to center the laser beam on the nozzle

- The head components are securely sealed to prevent dust from entering the optical section

The brand of the laser cutting machine can be changed according to the customer's preference

Fiber Laser Cutting HeadAutomatic height adjustment of the laser head relative to the workpiece surface, along with the laser beam autofocus system, maintains the optimal distance and precise beam focus throughout all cutting stages, resulting in increased quality, accuracy and uniformity in the cutting process.

- Cutting head with automatic focus

- Easy replacement of protective lenses

- Can be equipped with various types of laser sources with QBH

- Two beam center adjustment screws for easy centering of the beam in the middle of the nozzle

- The structure inside the head is completely sealed and prevents dust from entering the optical part.

The laser head brand can be changed based on customer feedback.

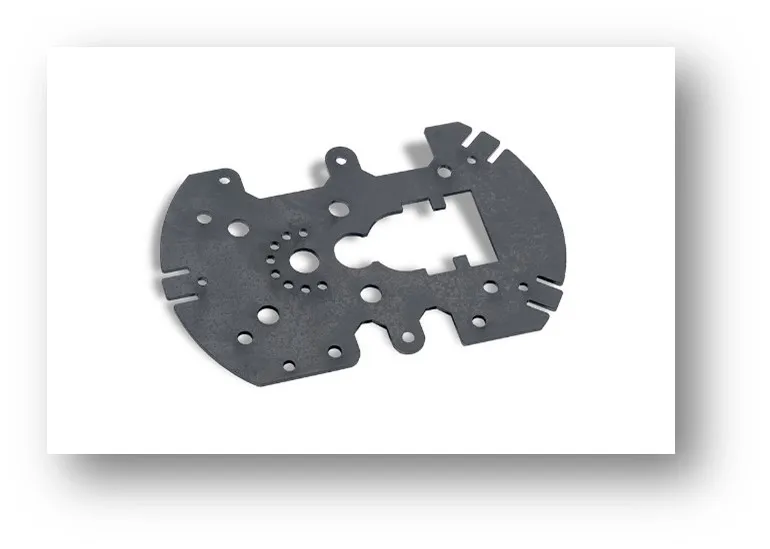

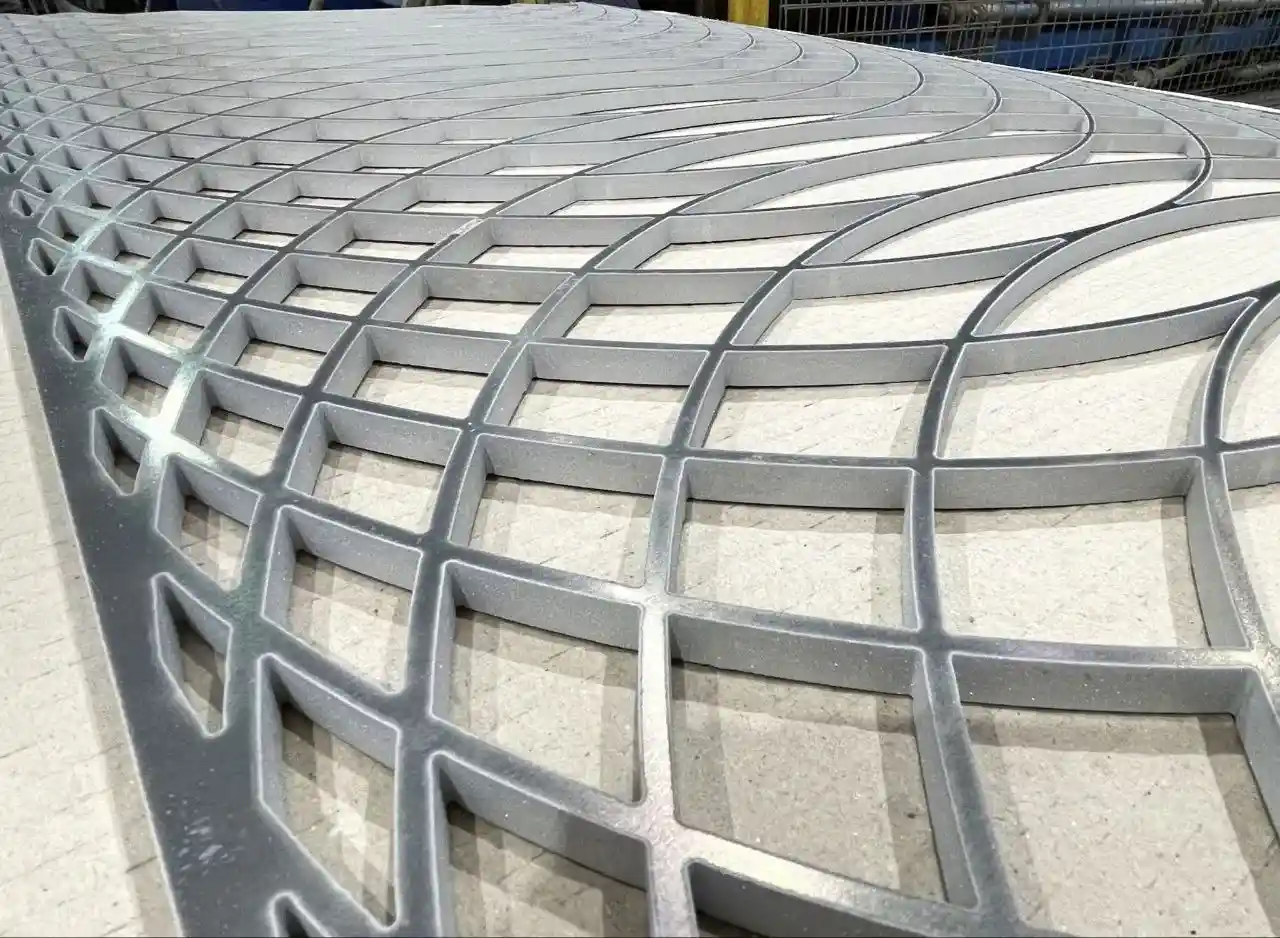

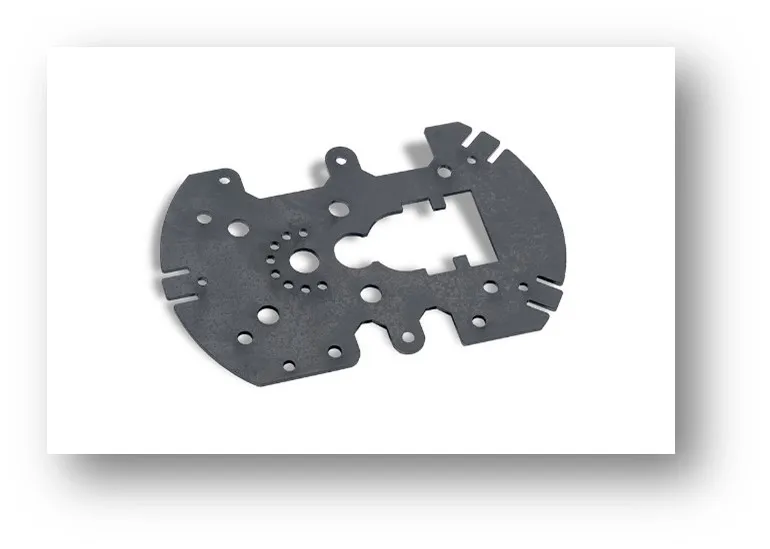

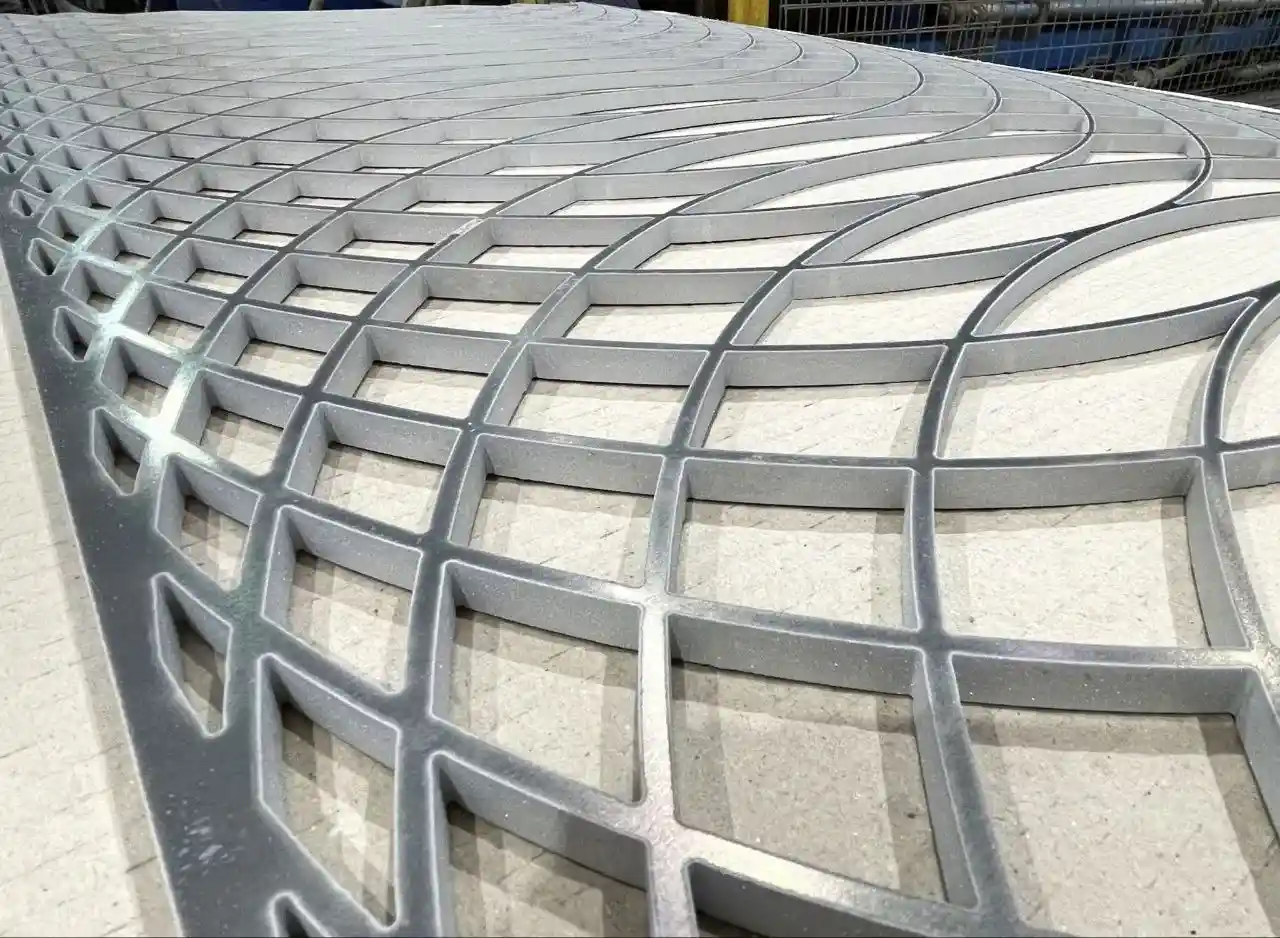

Cutting certain metal parts with the laser cutting machine

Fiber Laser Cutting Cooling System

Chiller

- The cooling system is designed with two separate channels to simultaneously cool the cutting head and the fiber laser.

- Precise temperature control within ±5°C

- Temperature control range: 5–35°C

- Constant temperature mode and other intelligent temperature control modes

- Smart alarm system to prevent water and temperature-related issues

- Compliant with CE, ROHS, ISO, and REACH standards

- User-friendly interface for temperature control

- Easy Modbus-485 connection to the fiber laser system

- Equipped with 220V and 380V power input lines

- Available in 220V and 380V models

The chiller brand can be customized according to the customer's preference.

The control system is equipped with IPC technology and offers advanced capabilities for complex cutting operations. In addition to controlling movement along the three main axes, the system can regulate the laser beam power based on sheet thickness, material type, and cutting parameters.

The control system is equipped with IPC technology and offers advanced capabilities for complex cutting operations. In addition to controlling movement along the three main axes, the system can regulate the laser beam power based on sheet thickness, material type, and cutting parameters.

Fiber Laser Cutting HeadAutomatic height adjustment of the laser head relative to the workpiece surface, along with the laser beam autofocus system, maintains the optimal distance and precise beam focus throughout all cutting stages, resulting in increased quality, accuracy and uniformity in the cutting process.

Fiber Laser Cutting HeadAutomatic height adjustment of the laser head relative to the workpiece surface, along with the laser beam autofocus system, maintains the optimal distance and precise beam focus throughout all cutting stages, resulting in increased quality, accuracy and uniformity in the cutting process.

Fiber Laser Cutting Cooling System

Chiller

Fiber Laser Cutting Cooling System

Chiller