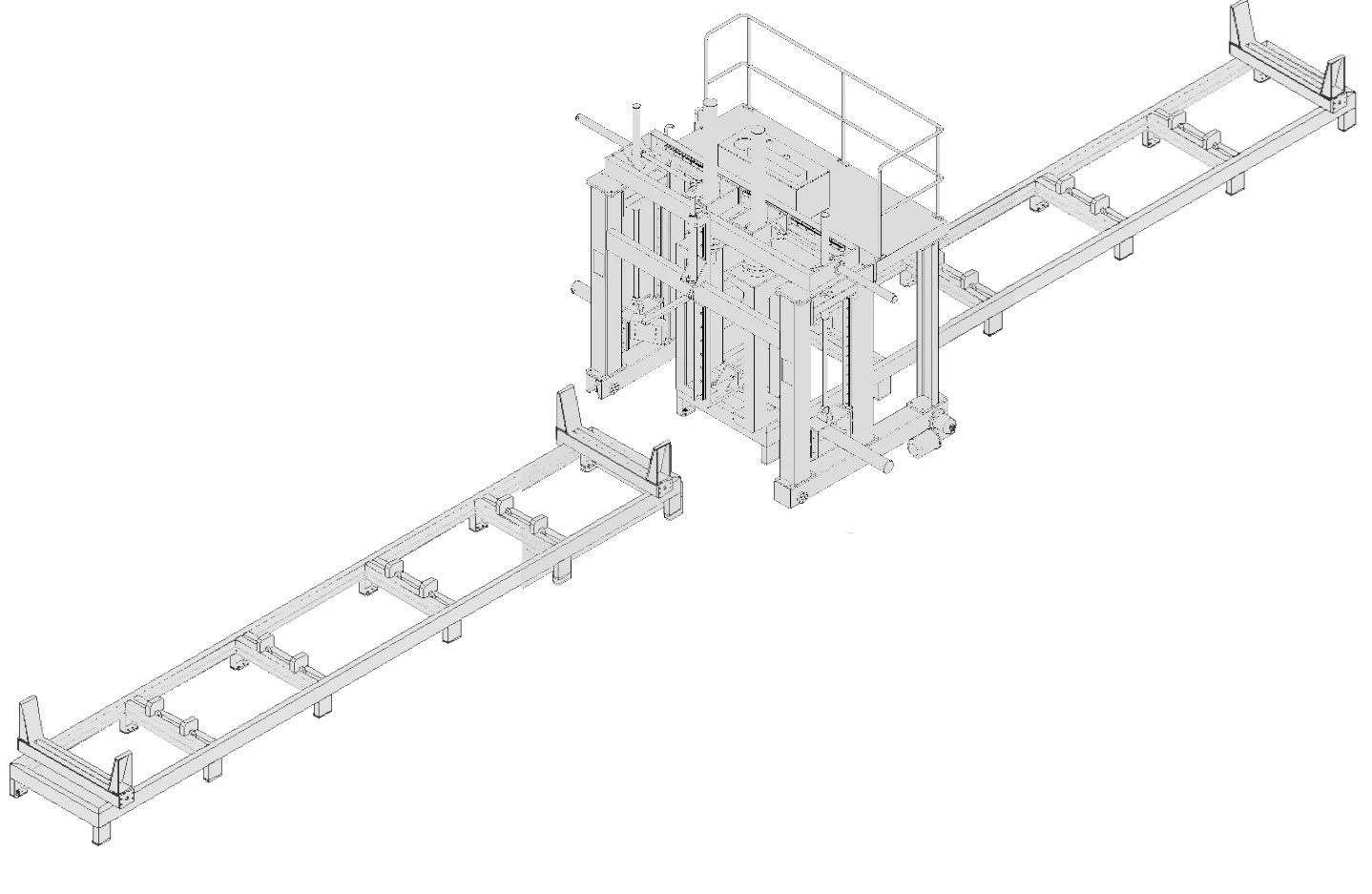

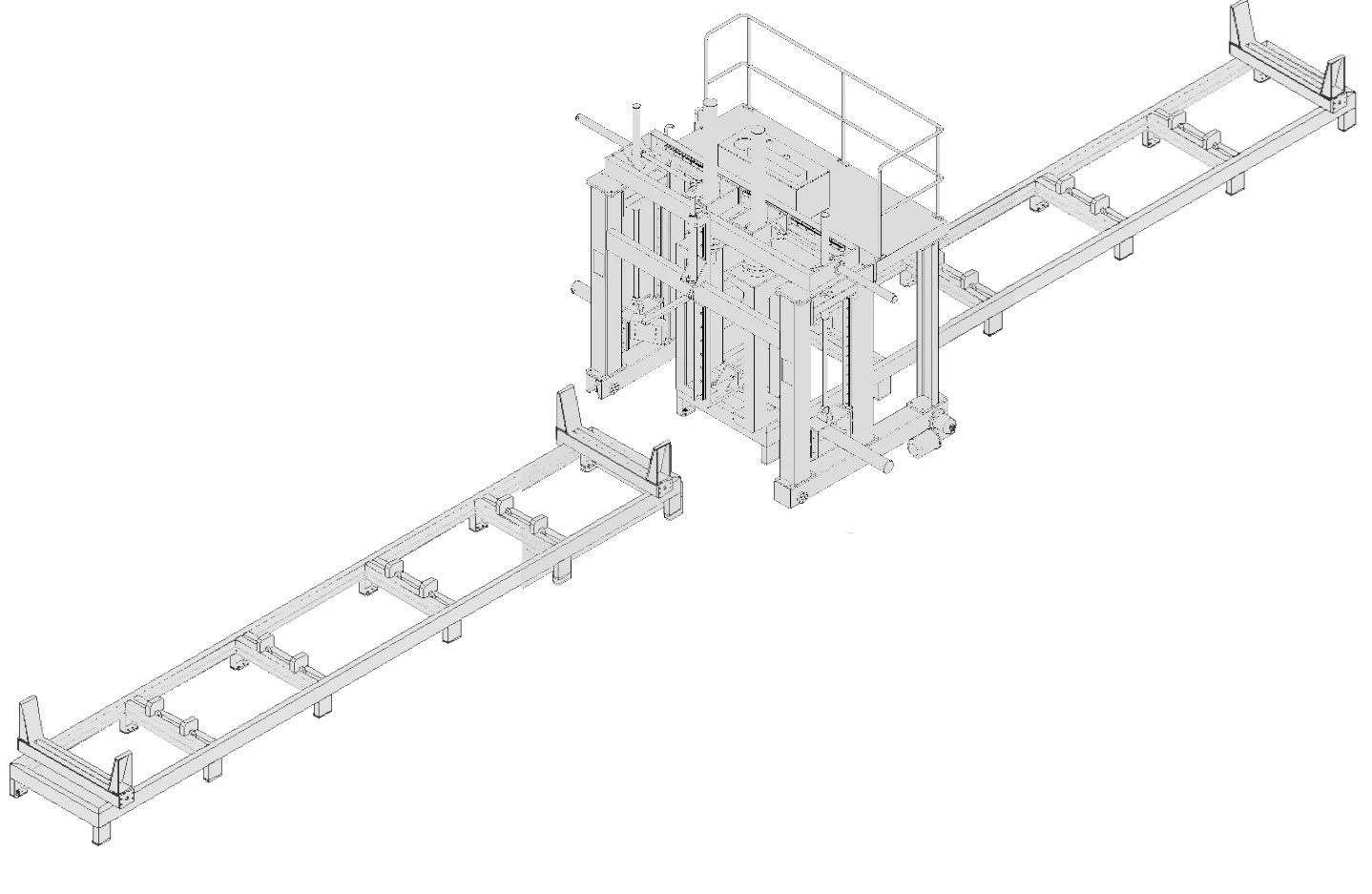

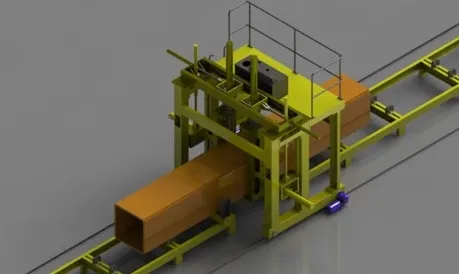

KARA Box Beam Assembly Machine

The steel

box beam assembling machine mainly consist of rail, travel device, rack, cross beam and platform, up press device, side press device, hydraulic system, electronic control system etc.

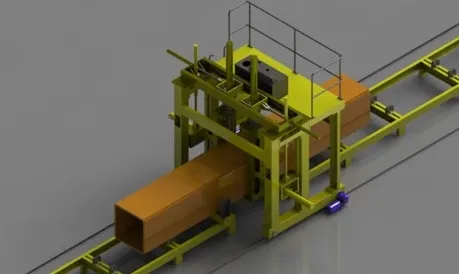

The travel device is two side driven. The motor reducing gear drives the machine to do longitudinal travel along the rail.

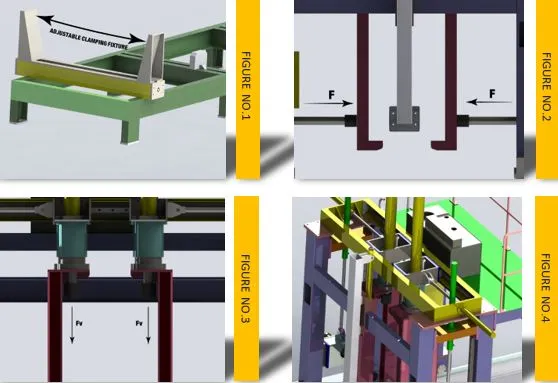

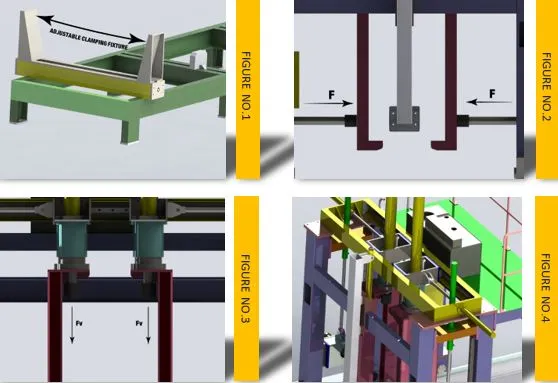

The zigzag hook will retract when the up pressing hydraulic cylinder presses. The positioning and clamping of the box beam bottom plate, cap and internal baffle is accomplished synchronously. And it can protect the base machine from pressure so that all the pressing force will be consumed by the workpiece, thus protecting the base machine from being damaged by the pressure.The base machine adopts box structure to get enough intensity. The mobile object is square sliding block which can bear greater forces and can be wearable. The complete hydraulic system is installed on the rack, so that the operation is quite convenient.

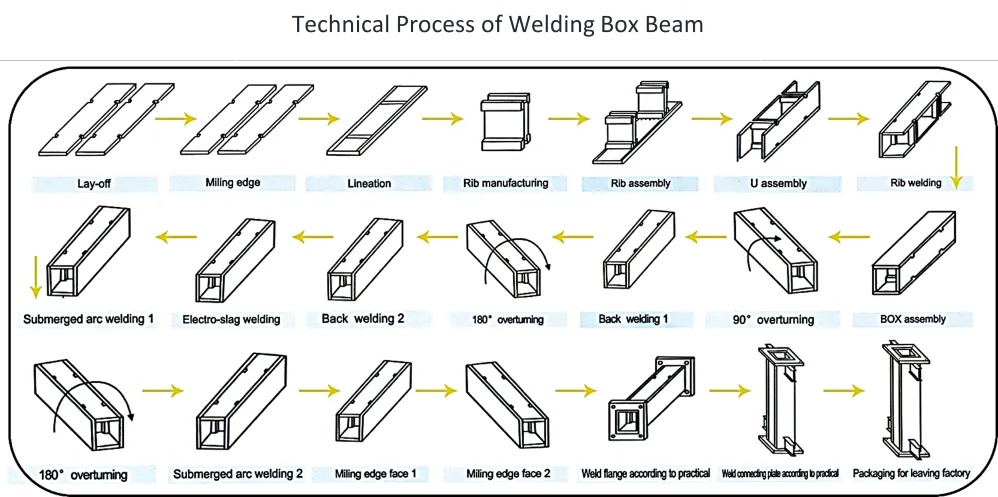

In order to ensure the positioning of plates on two side of the box girder during assembly, the workpiece frame is equipped with assist steering device for side plate adjustment, thus effectively ensuring the reliability of workpiece assembly.Box Beam Assembly MachineAccording to the processing requirements of the box girder, the four cover plates should be firmly fitted with the internal baffle to prevent the molten slag from leaking out during electroslag welding. Meanwhile, the internal baffles are distributed on the whole workpiece at intervals. KARA CO. developed the steel box beam assembling machine according to the processing feature of the box girder. This machine is the key equipment for box girder production. It is mainly used for box girder assembly.

- The steel box beam assembling machine mainly consist of rail, travel device, rack, cross beam and platform, up press device, side press device, hydraulic system, electronic control system etc.

- The travel device is two side driven. The motor reducing gear drives the machine to do longitudinal travel along the rail.

- The zigzag hook will retract when the up pressing hydraulic cylinder presses. The positioning and clamping of the box beam bottom plate, cap and internal baffle is accomplished synchronously. And it can protect the base machine from pressure so that all the pressing force will be consumed by the workpiece, thus protecting the base machine from being damaged by the pressure.

- The base machine adopts box structure to get enough intensity. The mobile object is square sliding block which can bear greater forces and can be wearable. The complete hydraulic system is installed on the rack, so that the operation is quite convenient.

- In order to ensure the positioning of plates on two side of the box girder during assembly, the workpiece frame is equipped with assist steering device for side plate adjustment, thus effectively ensuring the reliability of workpiece assembly.