KARA CNC PLATE DRILLING MACHINE

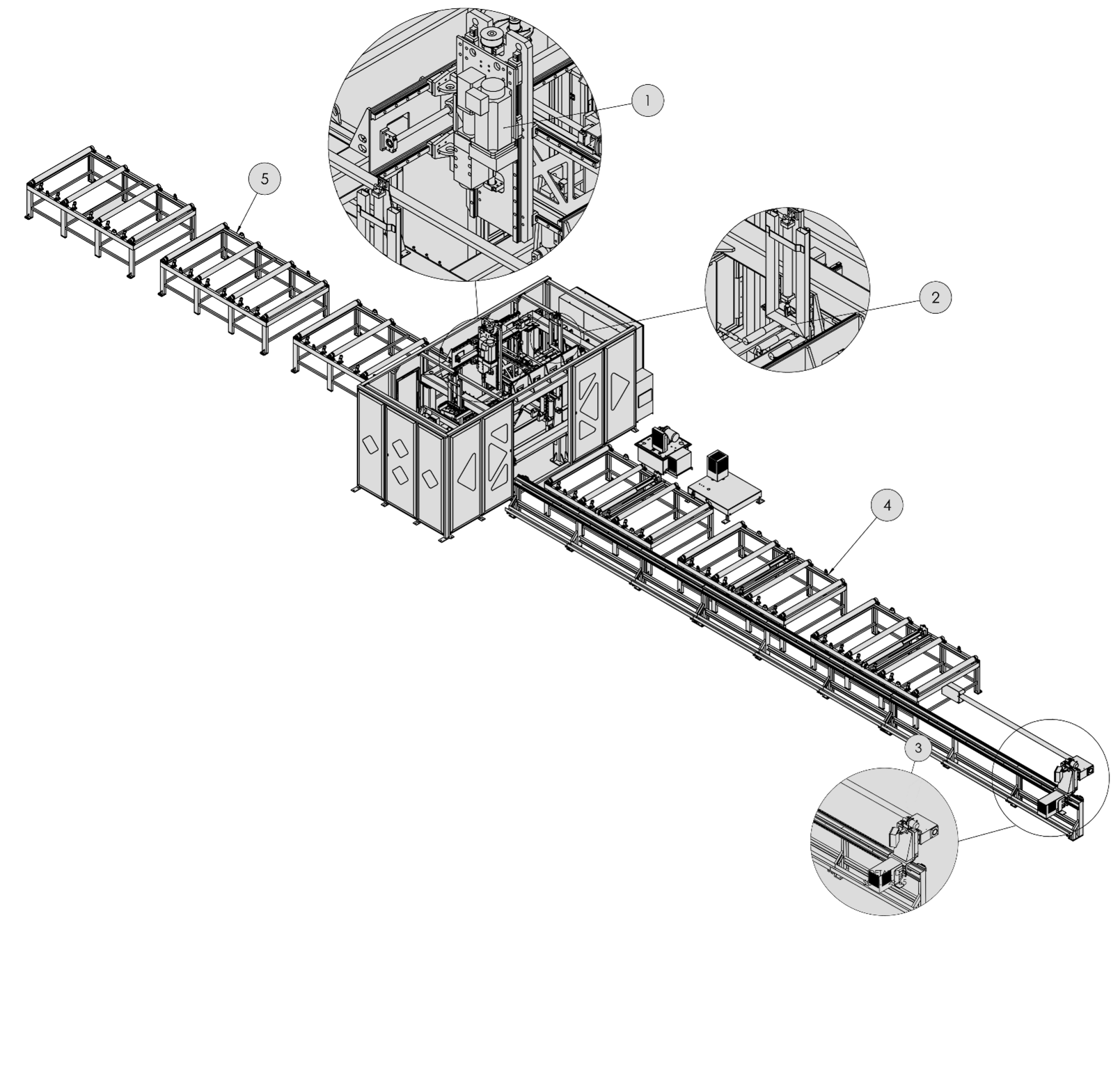

- Possibility of Drilling H-Beam and Original and Assembled Box Beams

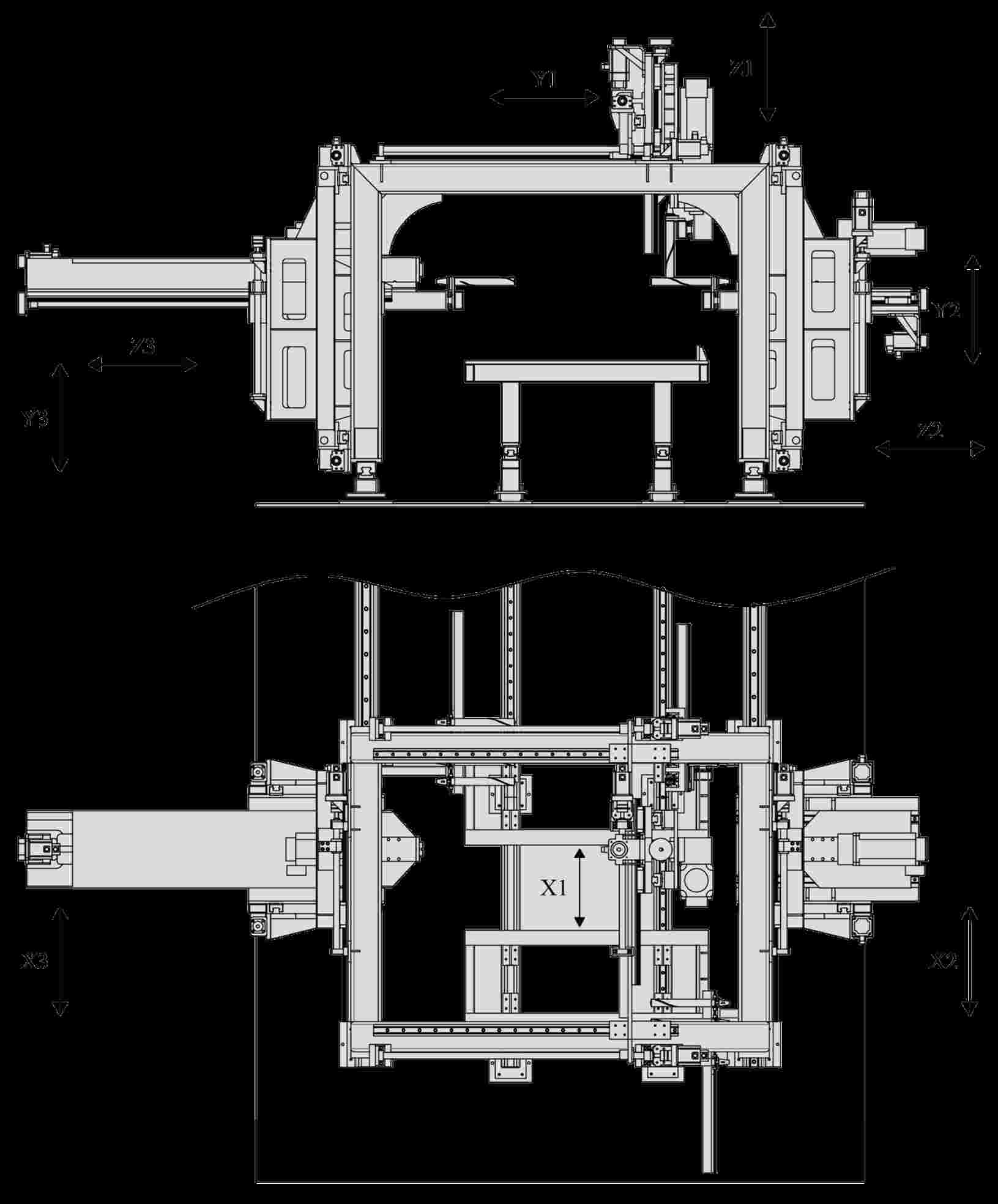

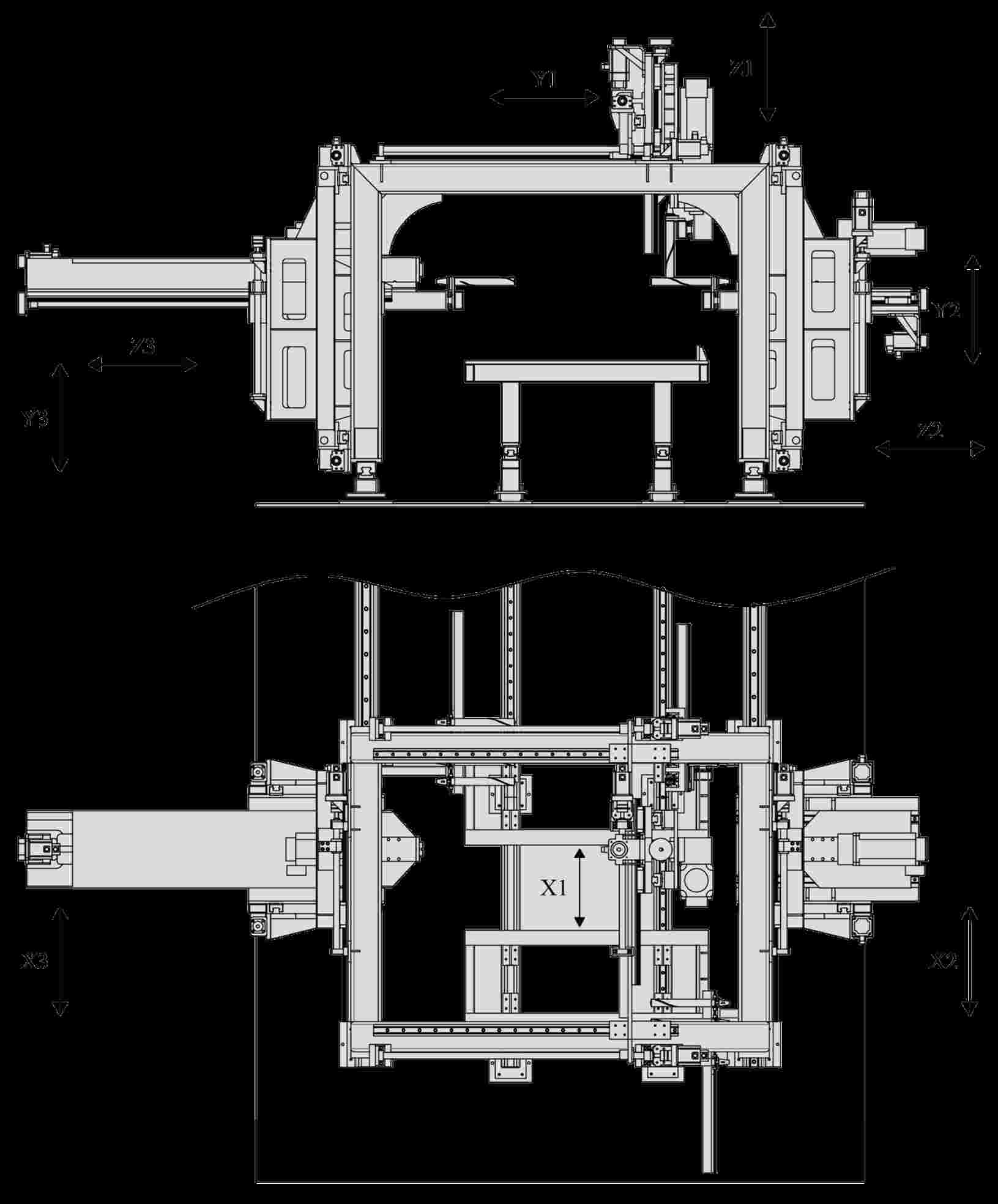

- Possibility of Three Spindles Simultaneous Performance for Asymmetric Drilling on H and Box Beam Wing and Flange

- Possibility of Tools Replacement for Each Spindle Independent of Their Performance While Drilling

- Work-Piece Clamping During Whole Drilling Process

- Using Double Ball Screw for Spindles Fast Movement While Positioning Drill Bit

- Ineffectiveness of Work-Piece Assembly Methods Such as Split H and Box Beam and Stud Welding on the Precision of Drill Bit Position

- Easy and Exact Installation Due to Using an Integrated Chassis along with Rails

- A Robust and Integrated Main Gate Structure for Sustainability and less Vibration during Drilling Process

- A Centralized Electric Power System for Noise Reduction, Cabling and Trouble-shooting Improvement

- Using an Air-Conditioning System than a fan in Power Center for Cooling

- Using an Optic Sensor to Locate Zero Point on Work-Piece than a Mechanical Step or Micro Switch

- Possibility of Connecting Controller to Internal Network-Cable-Wireless

- Having a Monitoring System for each Spindle

- Possibility of Drilling, Tape Cutting and Surface Milling on Spindles Simultaneously

- Equipped with Three Separate Hand Wheels for Each Process and Discrete Selection of each Axis

- A Robust Clamping System for Keeping the Work-Piece Constant While Drilling

- Equipped with CAN-OPEN Network System than the Old Analog System

Machine Control System

Promax (Italy)

NG WARP (Preliminary)

Technical Specifications: - New Processor Cold Fire 410 Mips

- 16 axes +/-10 V- 32 axes STEP/DIR

- 64 axes Can Open or Ethercat

- RAM 64 Mb, FLASH 64 Mb, 32Kb battery

- SSD 64 Mb with Fat 16

- 1 x Ethernet 10/100 TCP/IP

- 1 X ETHERCAT CoE

- 1 RS232 - 1 RS232/485

- Max 128 Inputs PNP 24 Vdc Opto

- Max 112 Outs 1,2 A 24 Vdc Opto

- 8 Analog Inputs 12 Bit

- Plc cycle

- Linear Interpolation, Circular, Elicoidal

- TCP/IP Modbus

- Component Framework .NET

- Gear and Ecam

- VTB language

NGWarp is the new controller Promax HIGH end. Fully compatible with NG35 but with a processor about 3 times more powerful. NgWarp integrates ETHERCAT on a dedicated Ethernet channel. Equipped with operating system RTOS (Real Time Operating System) you can manage sessions INTERPOLATION IN MULTIPROCESS.Axes:

- ANALOG +/- 10V max 16

- CAN OPEN max 64 and I/O

- ETHERCAT max 64 and I/O

- STEP/DIR. Max 32 freq Max 25 Mhz

- Through a second Ethernet port, you can manage the following protocols:

- MODBUS TCP/IP

- WEB SERVER

- RPC (remote procedure call)

- DEBUG

There are also two RS232 serial ports, one of which can be configured RS4845. Both ports operate the ODBUS RTU protocol.