(1 x 2)

(1 x 2)

| Subject | Descriptions |

|---|---|

| Effective workpiece dimensions | Length: 1000 mm, Width: 2000 mm, Thickness: 8 – 100 mm |

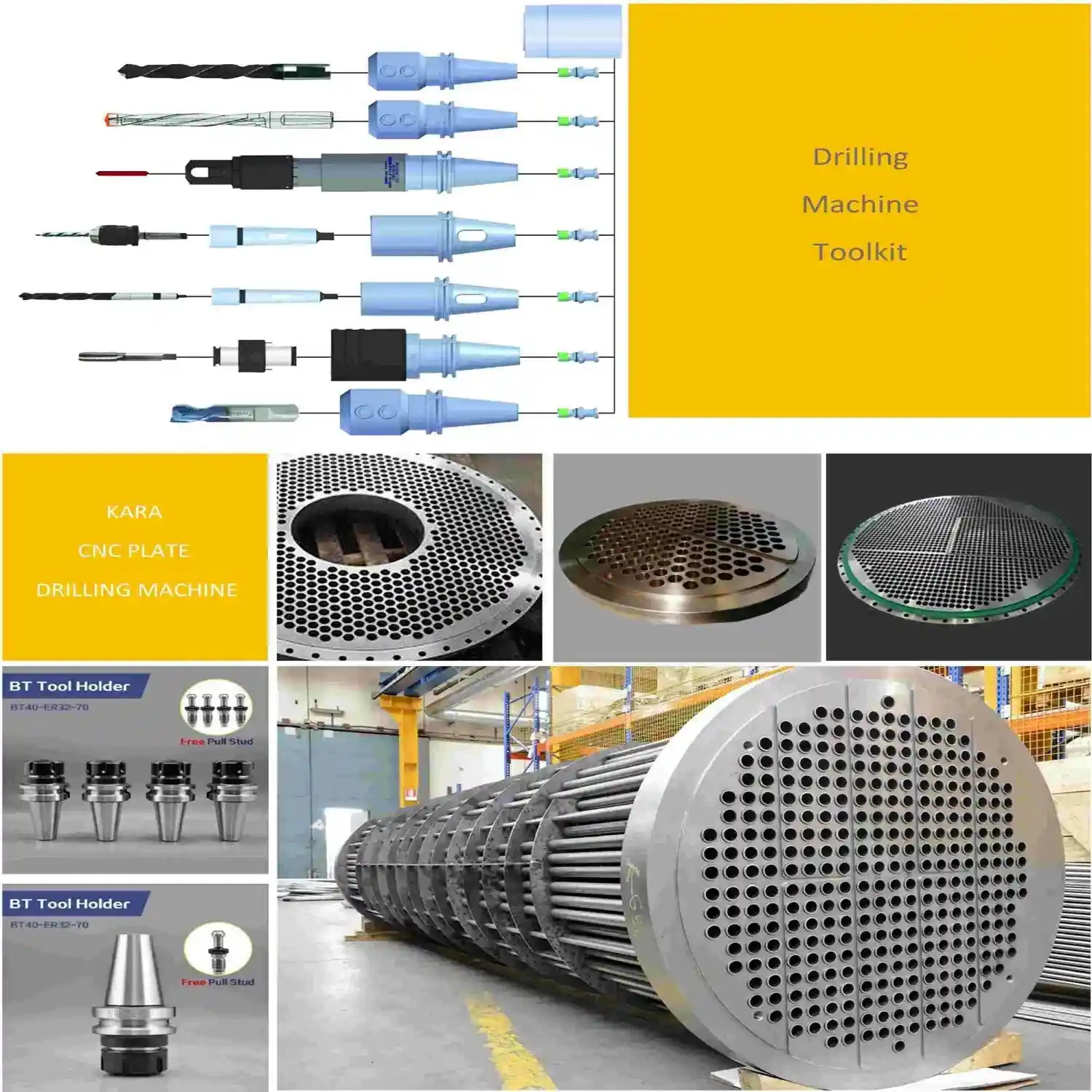

| Number of spindles | 1 Spindle – BT 40 |

| Number of machine axes | 3 AXES |

| Specifications and speed range of the spindle | AC Servo Motor: 7.5 kw Max Spindle Speed: 3500 Rpm Max Drilling Torque: 180 Nm - Spindle Taper: BT 40 |

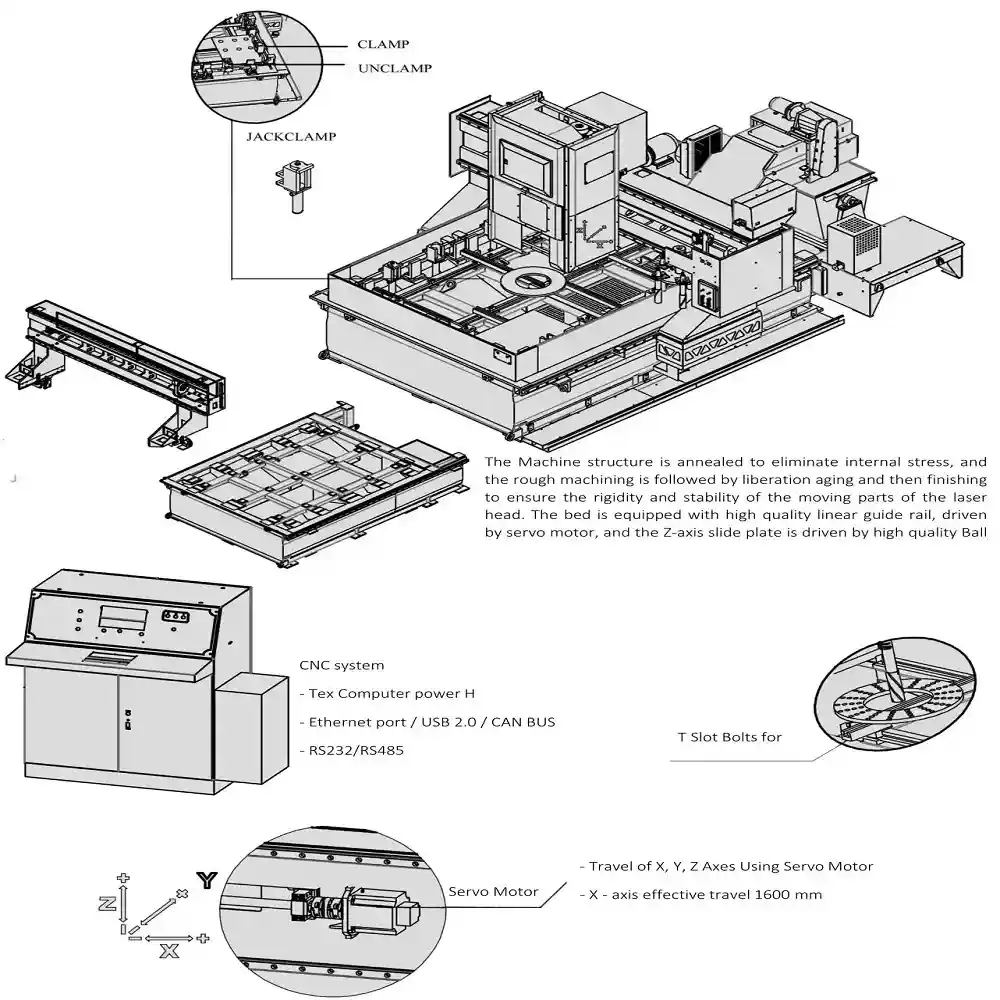

| Machine's control system | GSK - China |

| Machine's Control system features | G Code Generation (External Software) |

| Maximum linear velocity of Y axis (Longitudinal movement of the gate) | 5 m/min |

| Maximum X-axis linear velocity (Transverse spindle motion) | 7 m/min |

| Maximum Z axis linear velocity (Vertical spindle motion) | 5 m/min |

| Z-axis motion course (vertical spindle motion) | 650 mm |

| Machine's Movement accuracy | ± 0.02 mm |

| Machine's Drilling accuracy | Depended to drill life and quality |

| Type of drills | HSS: Min: 6 mm / Max: 35 mm (direct) HSS: Max 40 mm (with leading drill) Drill insert (spade drill) HSS Min: 10 mm / Max: 18 mm Index-able U-Drill: Min 24mm / Max 30 mm |

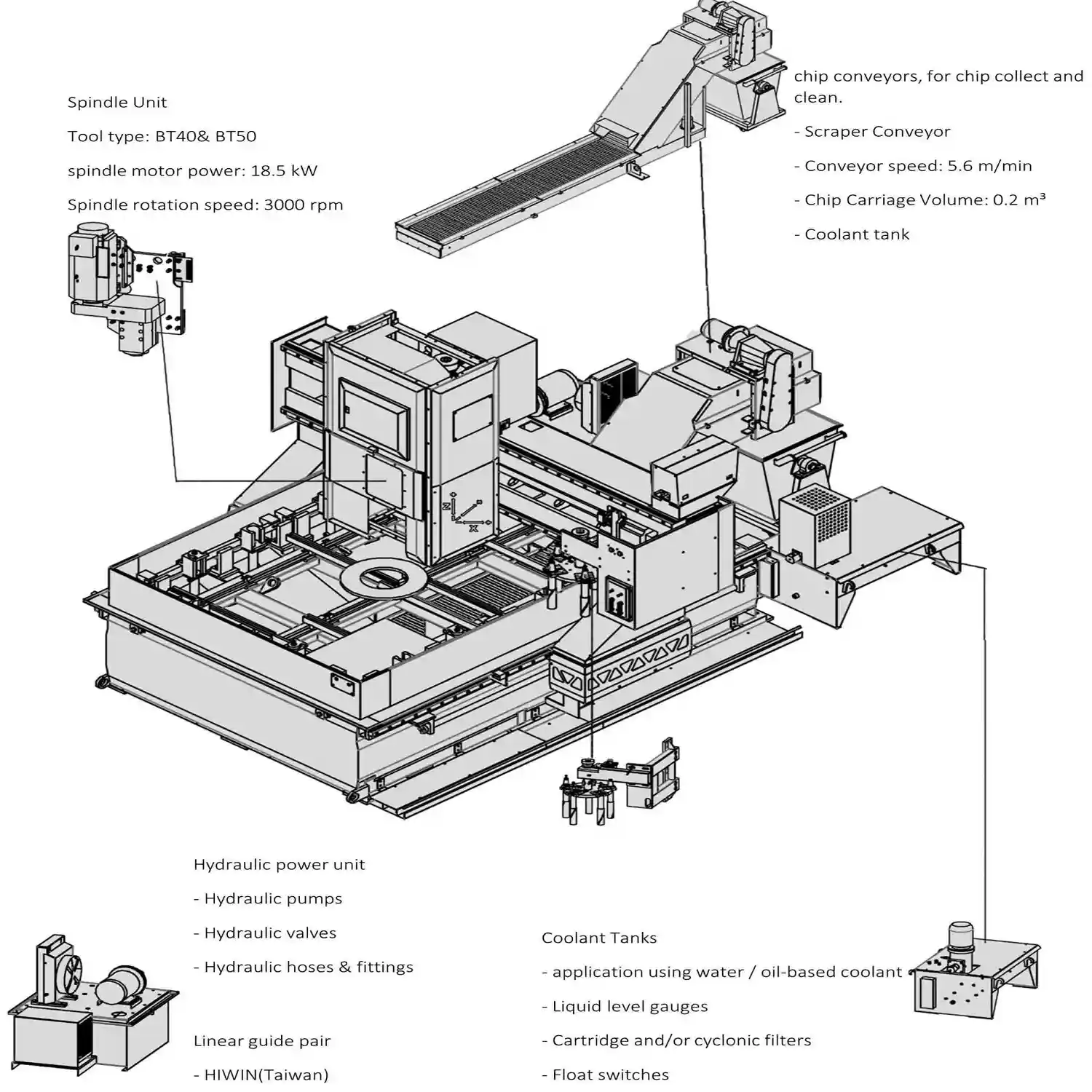

| Possibility of operating the hydraulic table of the device | Simultaneously from 4 sides of the table with separate hydraulic control |

| load capacity of machine's hydraulic table | 1 Piece up to 6 Pieces (middle & corner) |

| coolant system | Misting Coolant, External |

| Y-axis motor and gearbox (Longitudinal movement of the gate) | AC Servo Motor: 2Kw – 1000 rpm Pulley and Timing Belt fixed Ball Screw + Linear Guide (2 sets) |

| X-axis motor and gearbox (Spindle transverse motion) | AC Servo Motor: 2Kw – 1000 rpm Direct Flexible Coupling Ball Screw + Linear Guide |

| Z-axis motor and gearbox | AC Servo Motor: 2Kw – 1000 rpm Electrical Break Pulley and Timing Belt / Ball Screw + Linear Guide |

| Panel's degree of protection | IP 20 |

| Machine’s Electric Power Consumption (full load) | Nominal Current @ max. load = 380 V – 50 Hz – 3 Ph-90 A |

| Machine's collecting chip system (Optional) | Belt chip transfer conveyer - steel - movable - equipped with wheeled unloading bucket |

| Operator's application equipment | Coolant Sprinkler Guns/ compress air: Blower Guns |

| Overall Machine's Dimension (mm) | L: 3400 mm, W: 2800 mm, H: 2500 mm |

| Overall Machine's Weight (kg) | 4200 Kg |

Main Technical Specifications (1.6 x 2.2) / Type A

Main Technical Specifications (1.6 x 2.2) / Type B

Main Technical Specifications (1.6 x 2.2) / Type C

Main Technical Specifications (2.2 x 3.2)

[ninja_tables id="17035"