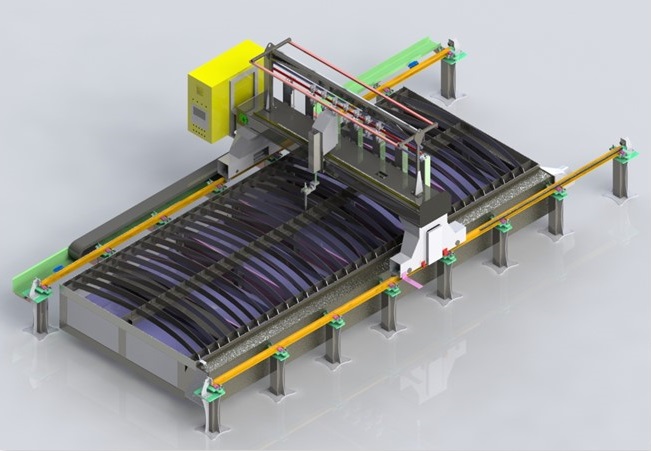

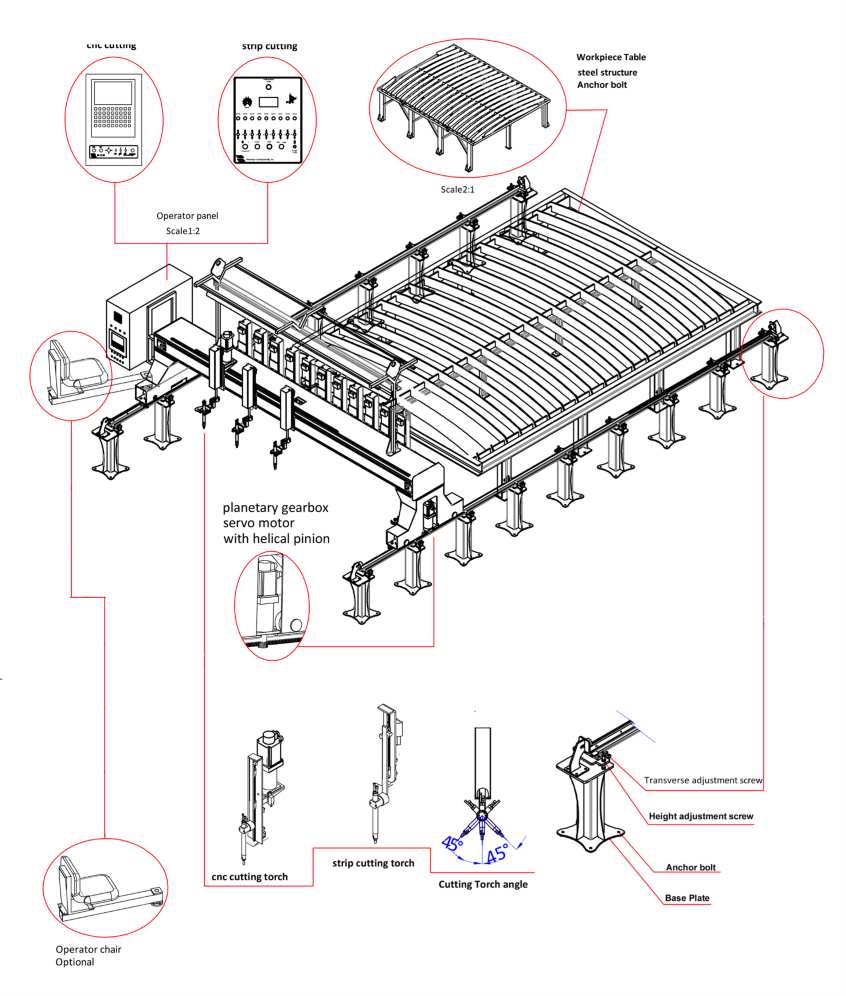

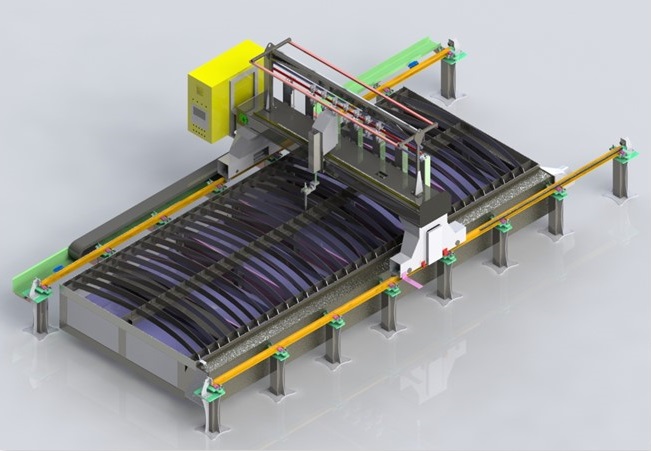

KARA CNC & Strip Cutting Machine

- Suitable for making exact cuttings in various shapes and sizes using Oxy-Fuel and Plasma cutting techniques.

- Equipped with an Oxy-Fuel transverse nozzle (connected by CNC controller).

- Having a robust and durable machining structure.

- Having a precise and high-speed linear motion using Servo Motor and planetary low-backlash gearbox.

- Equipped with two Servo Motors and low-backlash gearboxes at the two sides of machine for a constant and vibration less motion (gantry configuration).

- Possibility of transferring longitudinal motion force of cutting gate using a diagonal bevel gear for a fast and precise travel speed (Rack & Pinion).

- Possibility of linear movement of cutting nozzle on the linear ball bearings using a rack & pinion for fast and precise movements (Linear Guide).

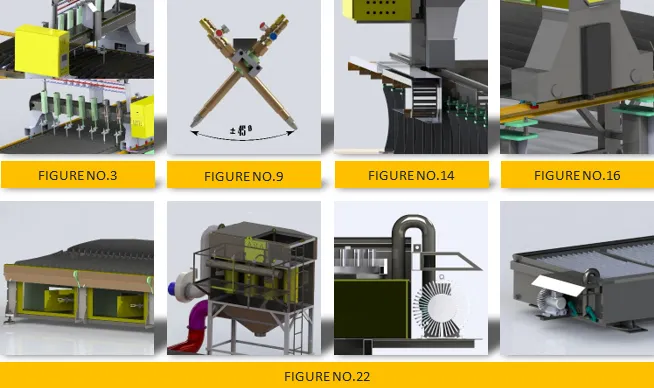

- Equipped with strip cutting nozzles control system (PLC-FATEK) with membrane (Polycarbonate) and easy operation.

- Equipped with automatic solenoid valves for each nozzle to avoid Oxygen and Gas waste, to adjust cutting flame and easy operation.

- Having a dust remover for slide rails.

- Equipped with a spring-applied control system for gearbox to protect damages resulting from operator fault while working.

- Equipped with robust, integrated and adjustable slide rails for unsmooth workshop surfaces.

- Having a set of robust steel belt tables which can be replaced easily.

- Possibility of installing automatic height adjustment for each strip cutting nozzle. (optional).

Machine Control System, Option #1

TexComputer (Italy)

CNC & Strip Cutting Machine، Technical Specifications:

- Equipped with 6 axillary machine zero points for placing workspace at 6 various locations of machine

- Transferring Files method: WIFI, Ethernet PORT, USB memory.

- 10-Inch-wide touch screen color monitor. (65000 colors, 1024x768 pixel)

- Controlling of Oxy-Fuel or plasma torch at various modes.

- Adjustable cutting torch Kerf.

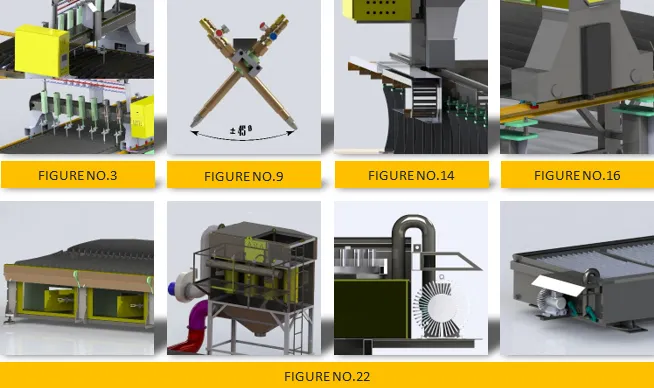

- Predefined figure library.

- Touch screen and graphic monitor (Persian and English)

- Backward cutting facility.

- Connectable mouse and keyboard (for editing codes).

- A Laser Pointer for Determination of Zero point. (optional)

- Adjusting plate angle by software.

- Possibility of Attaching Axis Beveling (optional).

- G-Code Generator: Pro Nest Software Program (in office).

- CNC Automatic Torch Height Controller (for plasma torch).

- Fully-Closed-Loop Servomotor Control System.

- Cutting Type Software Selection (Oxy-Fuel/Plasma).

- Controller Technology (ITALY, 2016).

Machine Control System, Option #2

MicroStep (China)

- Large LCD: 15” CC-Z4 Cutting Numerical Controller Four Torches separately control. It has many cutting types and it works well in worse environment.

- Stronger Industrial Embedded Core.

- Support various compound cutting, plasma, flame, laser, line-draw, drill, can steady work in the electromagnetism environment.

- Support different cutting, such as cutting, such and so on. It can stably work under complicated electromagnetic environment.

- Transferring file method: USB

- Adjustable cutting torch: Kerf

- Predefined figure library.

- Backward cutting facility.

- G-code Generator: pronest software programs (in office).

- Open loop servo control.

- Oxy- fuel & plasma height control: External

- User friendly.

- Simple operator training.

| PROCESSOR | DISPLAY | DIMENSION | WORKING TEMPERAYURE | STORE TEMPERATURE |

|---|

| Industrial ARM processing chip | 15" colors | 390*418*64mm | 0°C~55°C | -40°C~60°C |

| NO. OF LINKAGE AXIS | I/O CONTROL | CONTROL PRECISION | STORE SPACE | HIGHEST SPEED |

|---|

| 2-6 Axis | Input x 32

output x24

| 0.001 mm | 8G and it supports U disk | 36 m/min |

KARA PLASMA 200A

CNC & Strip Cutting Machine، Application

Suitable for cutting all metal industries with easy operation, high velocity and qualityCapability of cutting carbon steel with a 0.5mm-25mm thickness as well as stainless steel with a 0.5mm-20mm thickness and aluminum 0.5mm-15mm.

Process Description

KARA Plasma Cutting uses a concentrated electrical arc which melts the material through a high temperature plasma beam. All the conductive metals such as carbon steel, alloy steel, aluminum, copper, etc. can be cut. In this process, the work-pieces can be cut by using ionization of gas and jet ions which are expanded with a high velocity from a very narrow orifice. The contact of these ions with work-piece produces a high amount of heat causing the area to be melted. The plasma gases can be compressed air, Nitrogen, Oxygen or a mixture of Argon/Hydrogen. Since there is 5-7 times increase in cutting speed compared to Oxy-Fuel cutting, there will be fewer dead times (without pre-heating). Indeed, the high speed and no need to Oxy-Fuel, there a considerable reduction in the plasma cutting price compared to Oxy-Acetylene welding.

Features

- Continuous current Control from 20 A to max (thyristor control)

- Tough work shifts for a long time cutting

- Thermostat for protection against overload & overcurrent

- Twin filter drier

- Output current display

- Air pressure gauge

- Possibility of being used with low air pressure

- Maximum Current limiter

- Tow eyelet for easy transportation

CNC & Strip Cutting Machine،Accessories

Water cooler unit for plasma cutting torch cooling.Plasma cutting torch (air/water Cooled).Longitudinal cutting carriage with

capability of straight torch installation (optional).