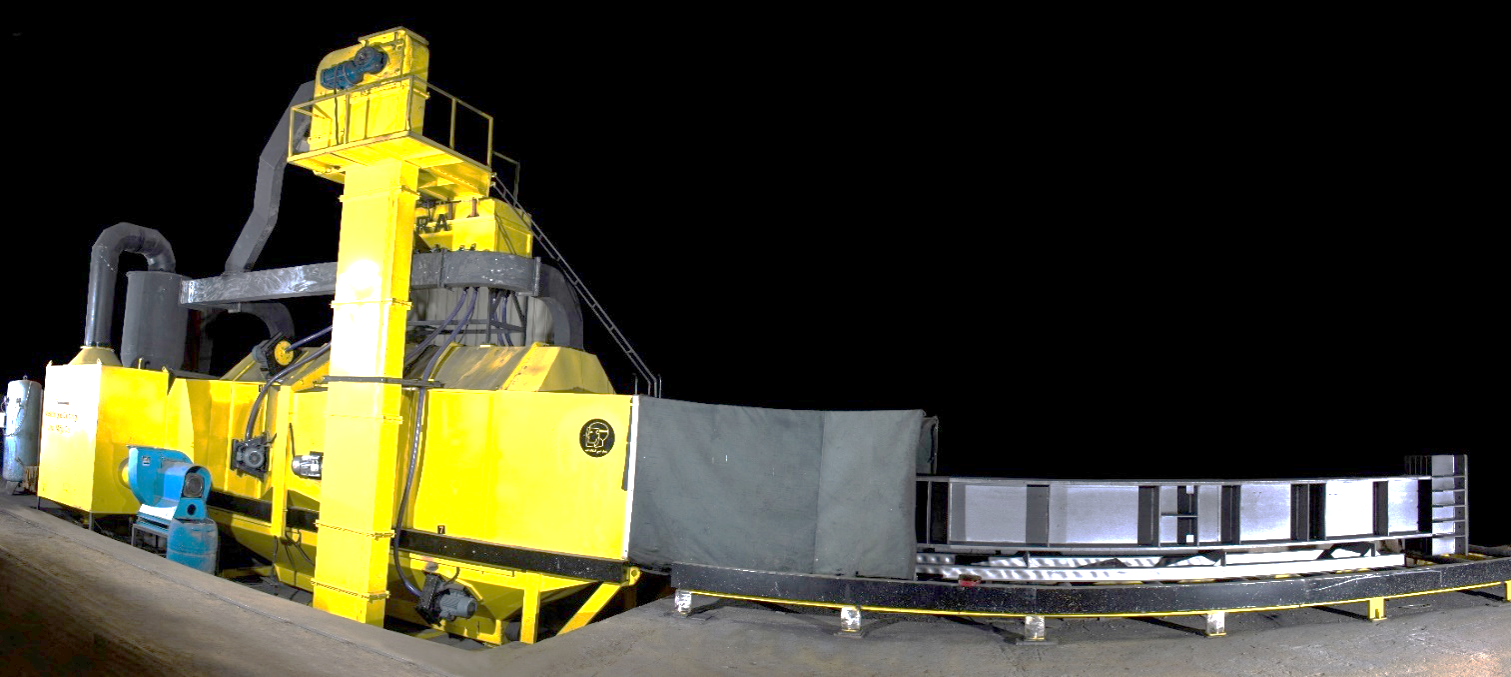

KARA SHOT BLASTING MACHINE

Working method at the shot blast machines:

In these machines, steel bullets (shot-shot) after entering the centrifugal turbines of the device are accelerated and sprayed on the surface of the part, which due to these high-speed and consecutive collisions of the bullets, shooting operations are performed in these devices. Shot blasts are commonly used in industrial work and high-volume parts, as well as on large flat surfaces such as ship hulls and hall floors, and in a few cases in decorative work - antiquities and framing.

Using shot blasting machines, operations can be performed:

- De-rusting - sanding - and painting the inner and outer surfaces of the parts.

- Peeling the surfaces of all forged parts.

- Grinding the surfaces of parts (using grit) to optimize glazing and Teflon operations for better

durability and quality.

- Preparing the surfaces of parts for various types of industrial-decorative or paint plating.

- Matting - cleaning and preparing parts for presentation in the market can be done.

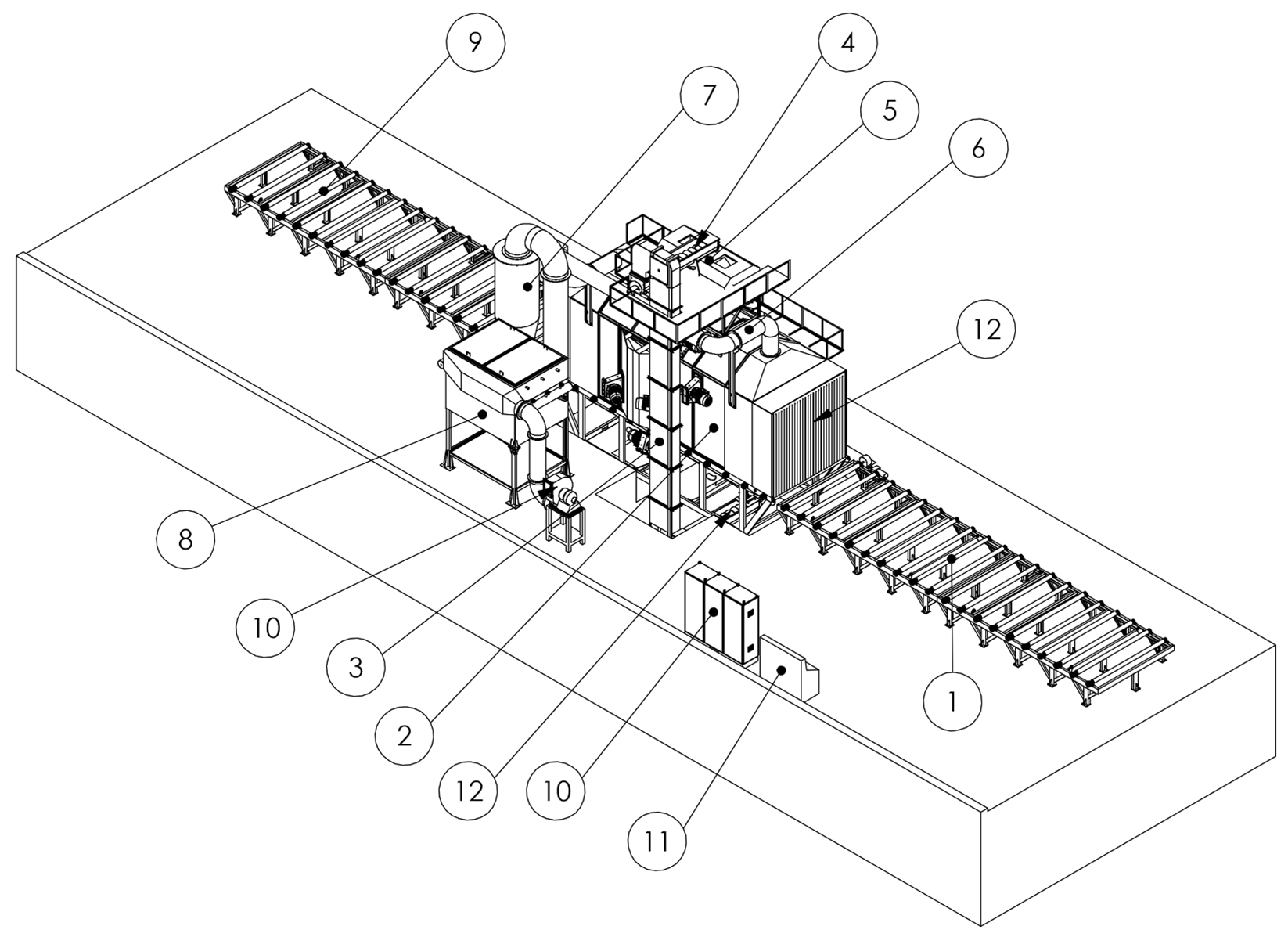

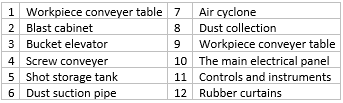

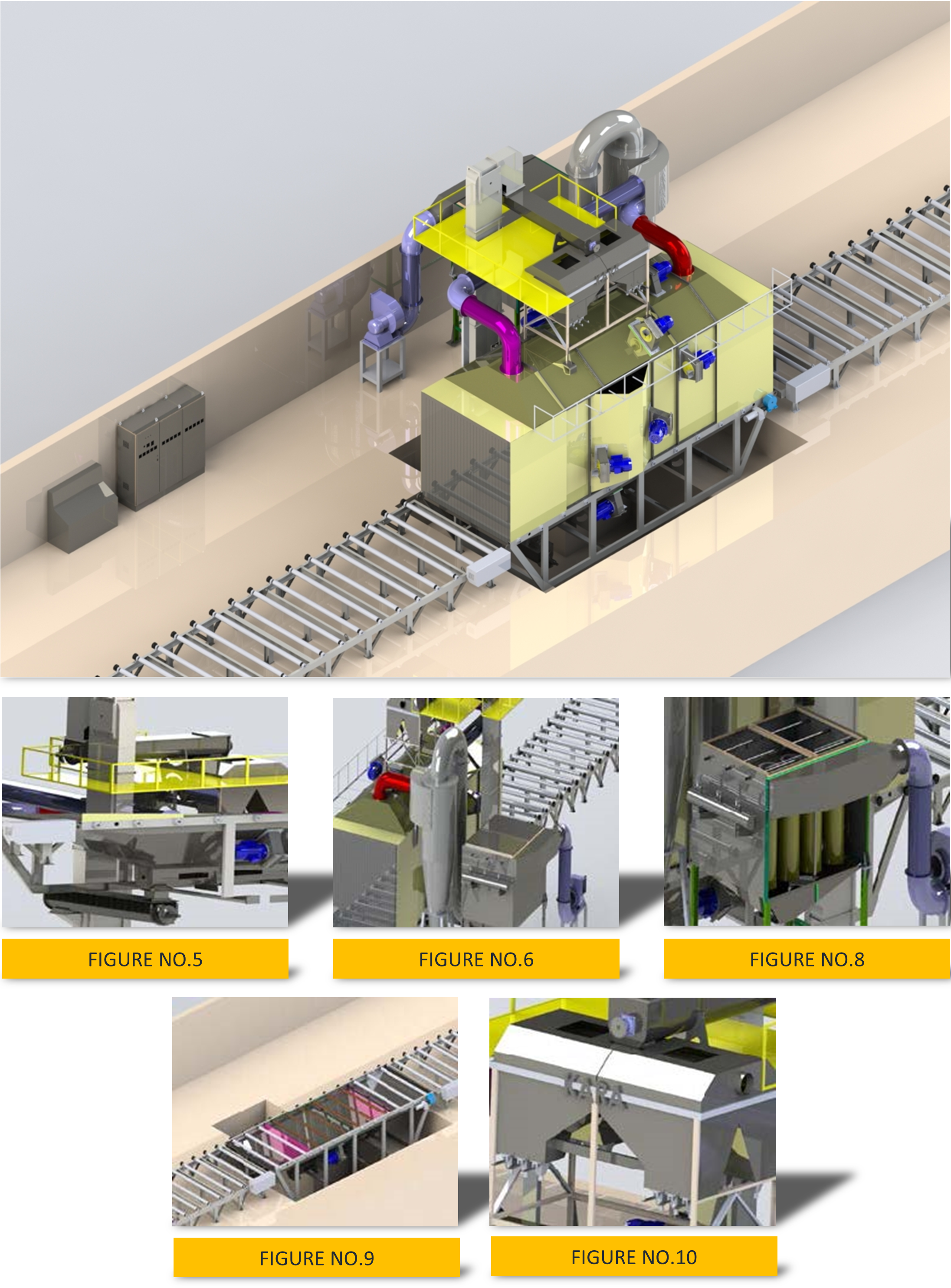

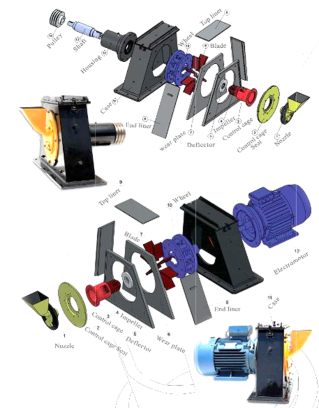

Components of shot blasting machines

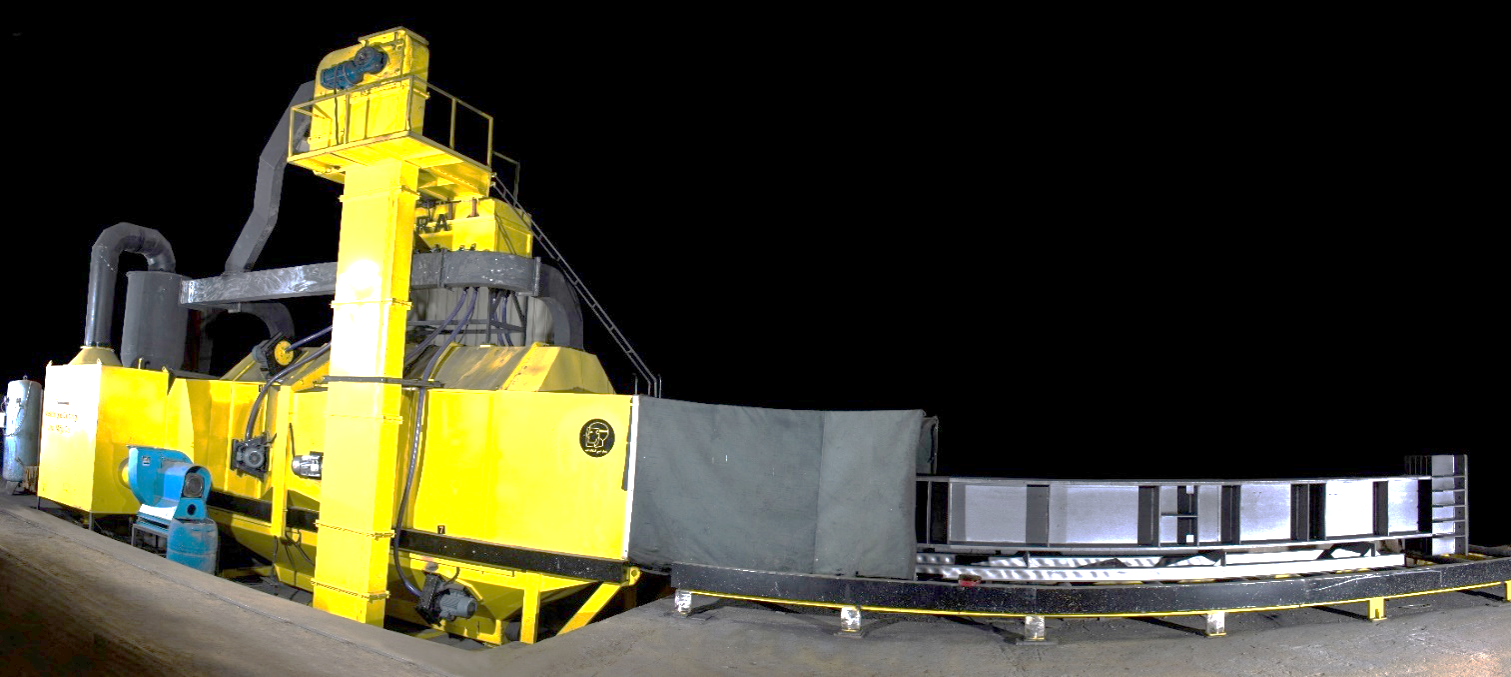

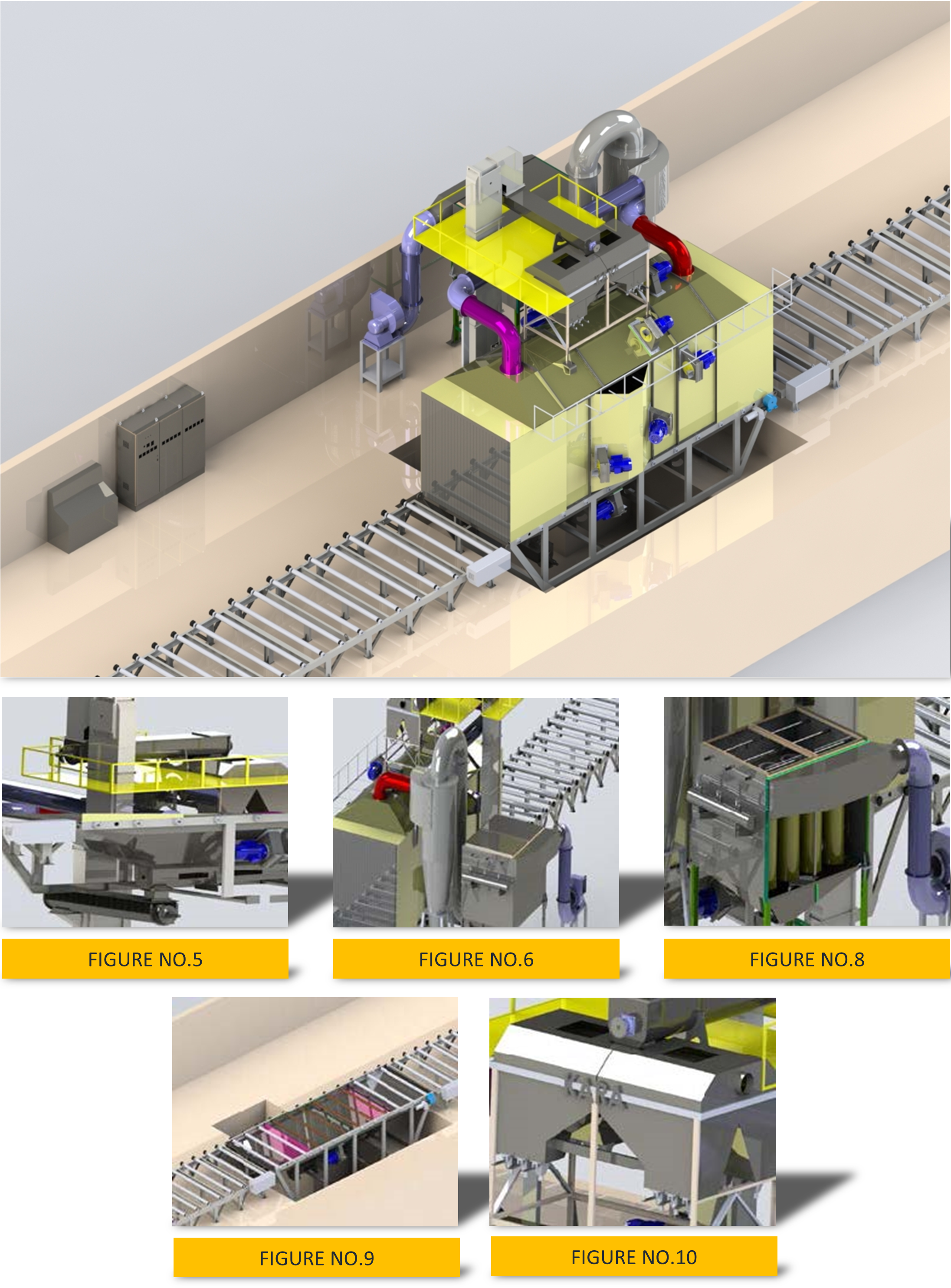

Shot blasting machines are generally divided into 5 parts, which in case of failure of any of these parts, the saber work of the machine parts will be disrupted. In general, coordinated work between these parts allows simultaneous shooting operations. These parts are:

- Roto blast (shot blasting turbines)

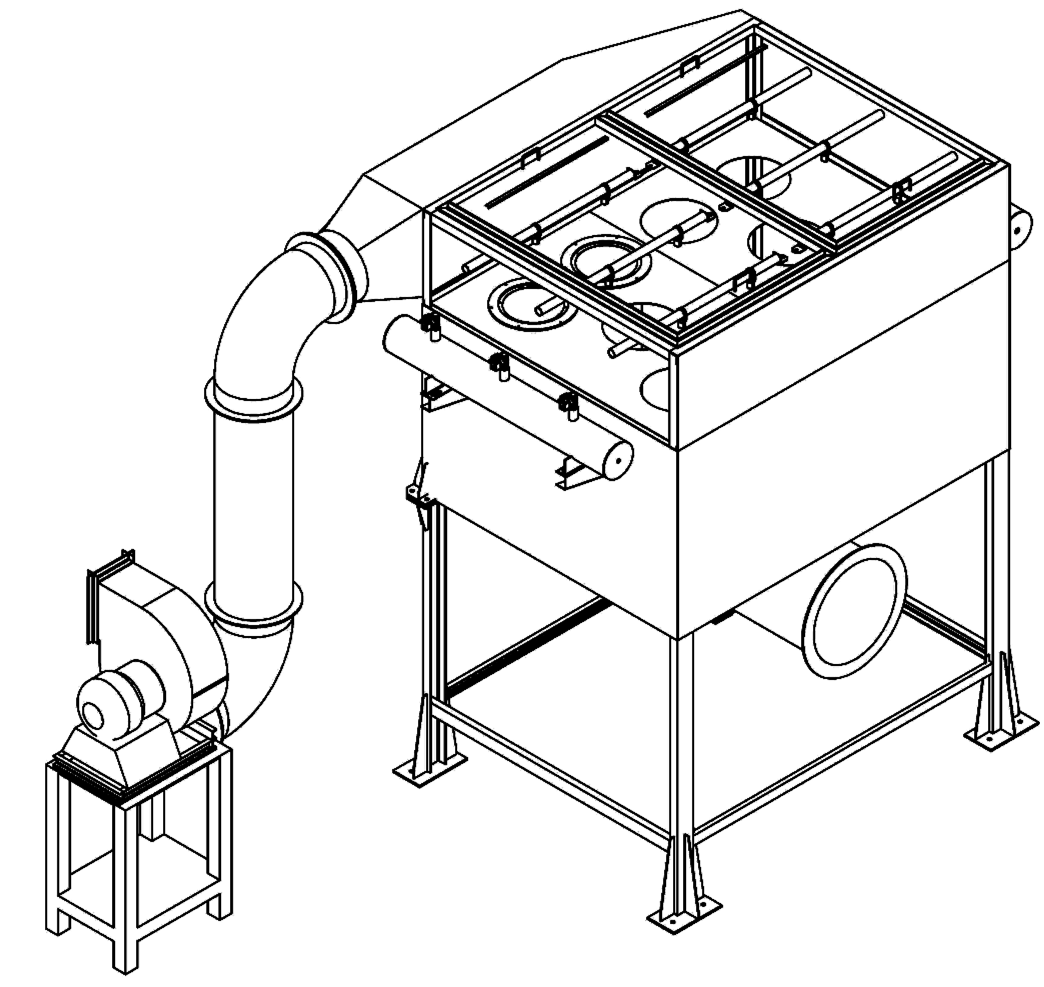

- Blast Cabinet

- Elevator Shot (device ball lift)

- Dust Collector Systems (which includes the dust filter outlet of the device)

- Tables for transferring sheet beams into the channel

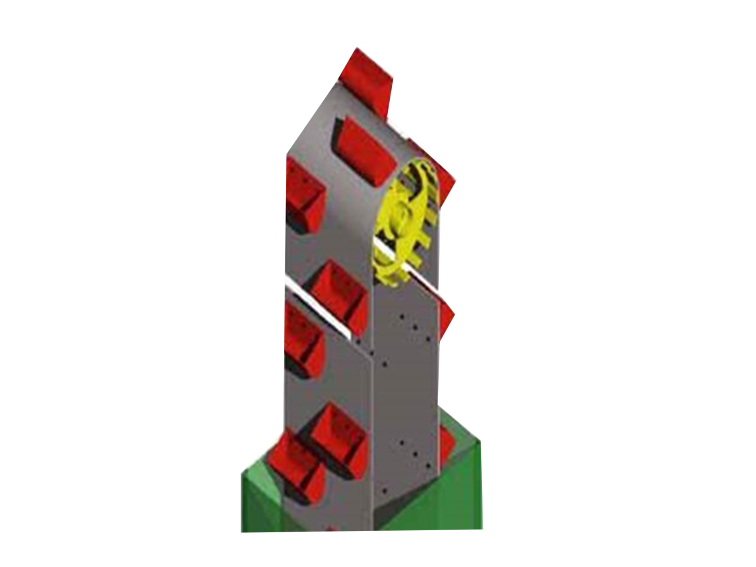

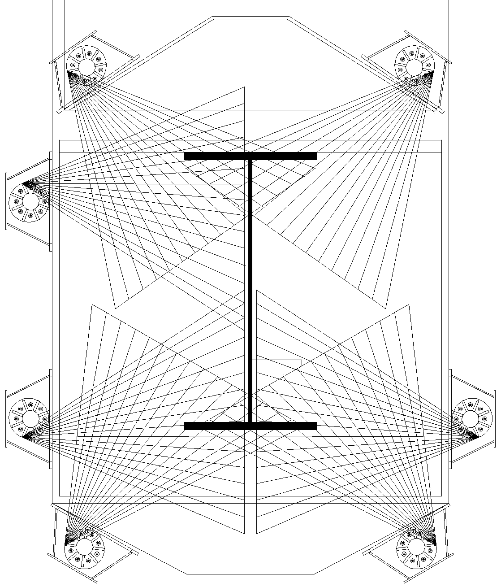

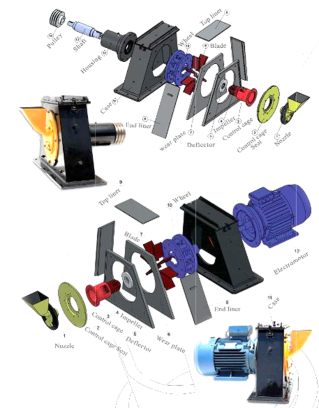

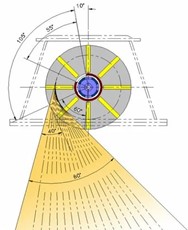

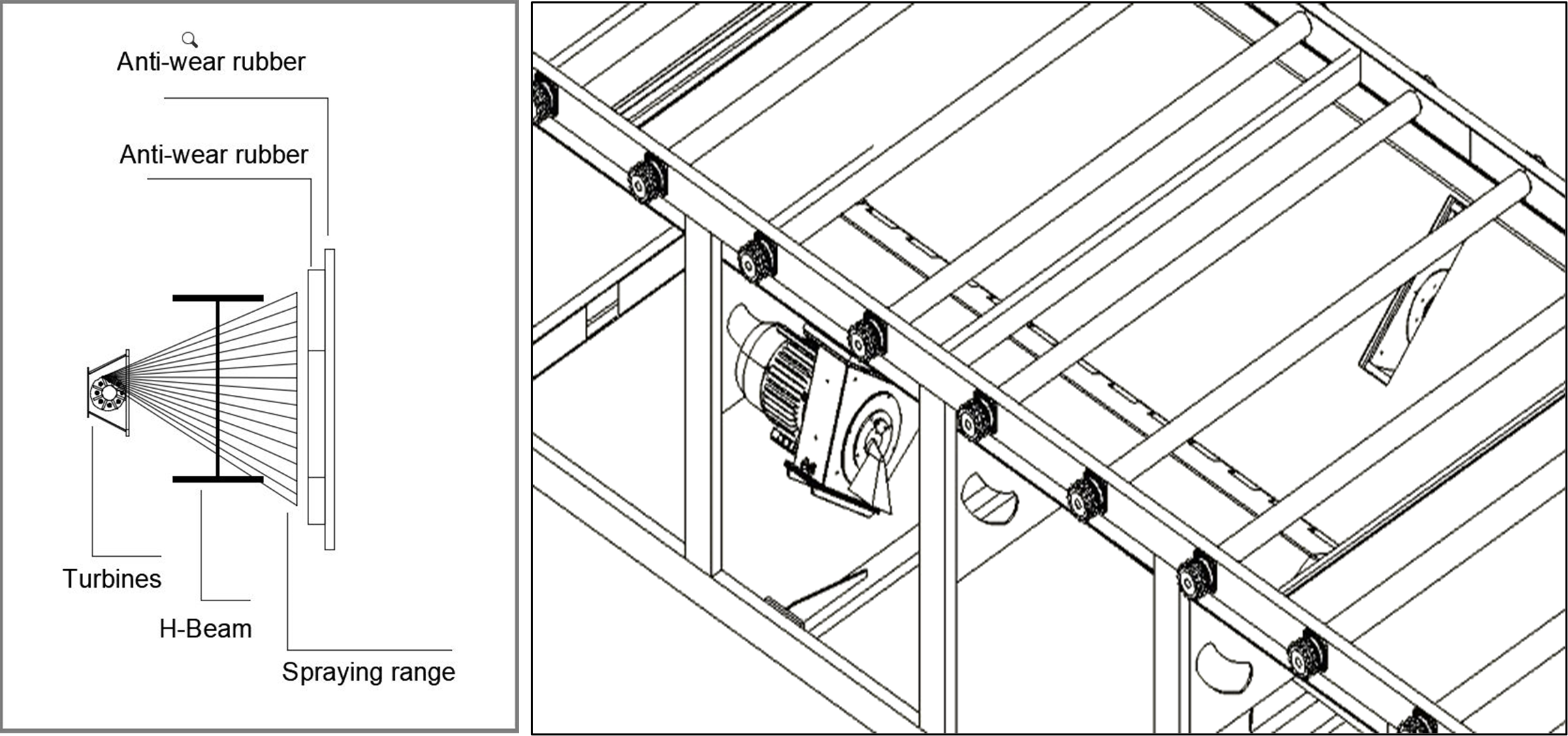

Shot Blasting Turbines

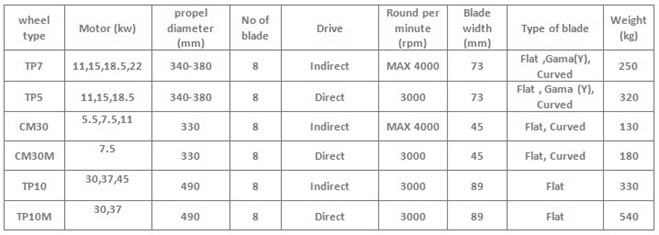

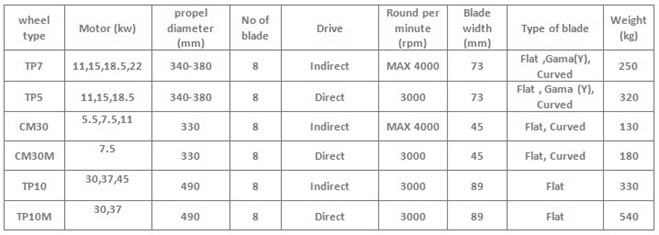

Shot blasting turbines is manufacturer of Different Kinds of Centrifugal Wheel.

Our products are in two types:

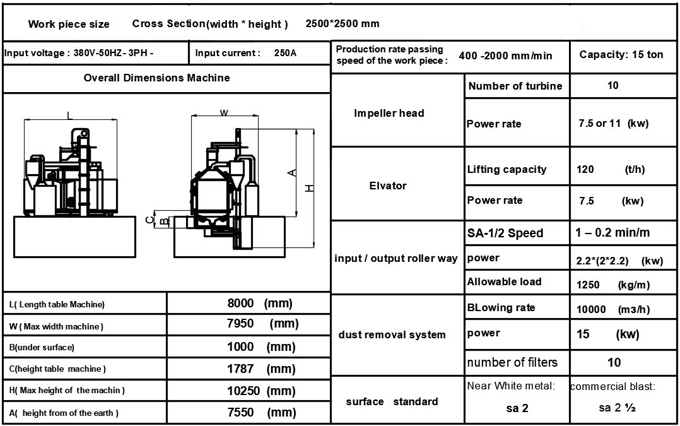

Number of turbines: 10 set / Wheel Type: TP7 / Motor: 11 kw

- wheel with straight blade (type flat)

- wheel with curved blade (type Gama, curved)

Curved type blades have following advantages comparing to straight types:

- Smaller diameter

- Less noise

Our Centrifugal Wheel may be assembled in two types:

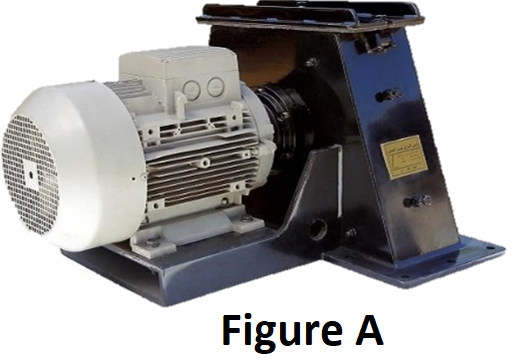

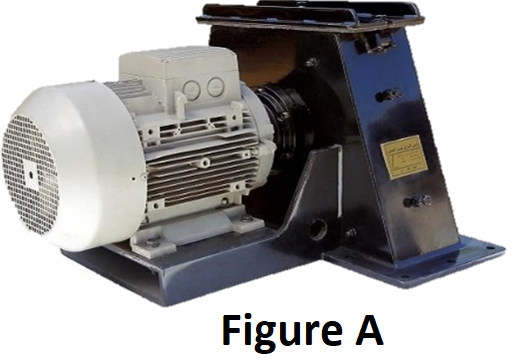

- With motor direct coupled - Figure A

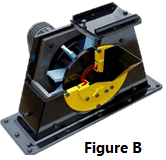

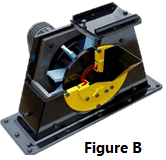

- With motor indirect coupled (with a shaft) - Figure B

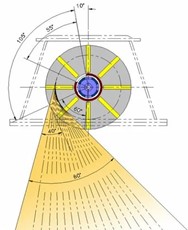

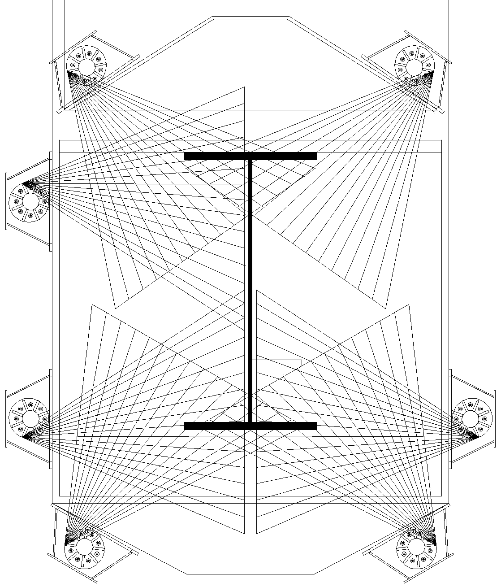

The blasting angle can be set by means of an externally adjustable control cage. It serves to concentrate the blast directly at the Hot Spot (the area where the work pieces are optimally exposed to the Shot stream)

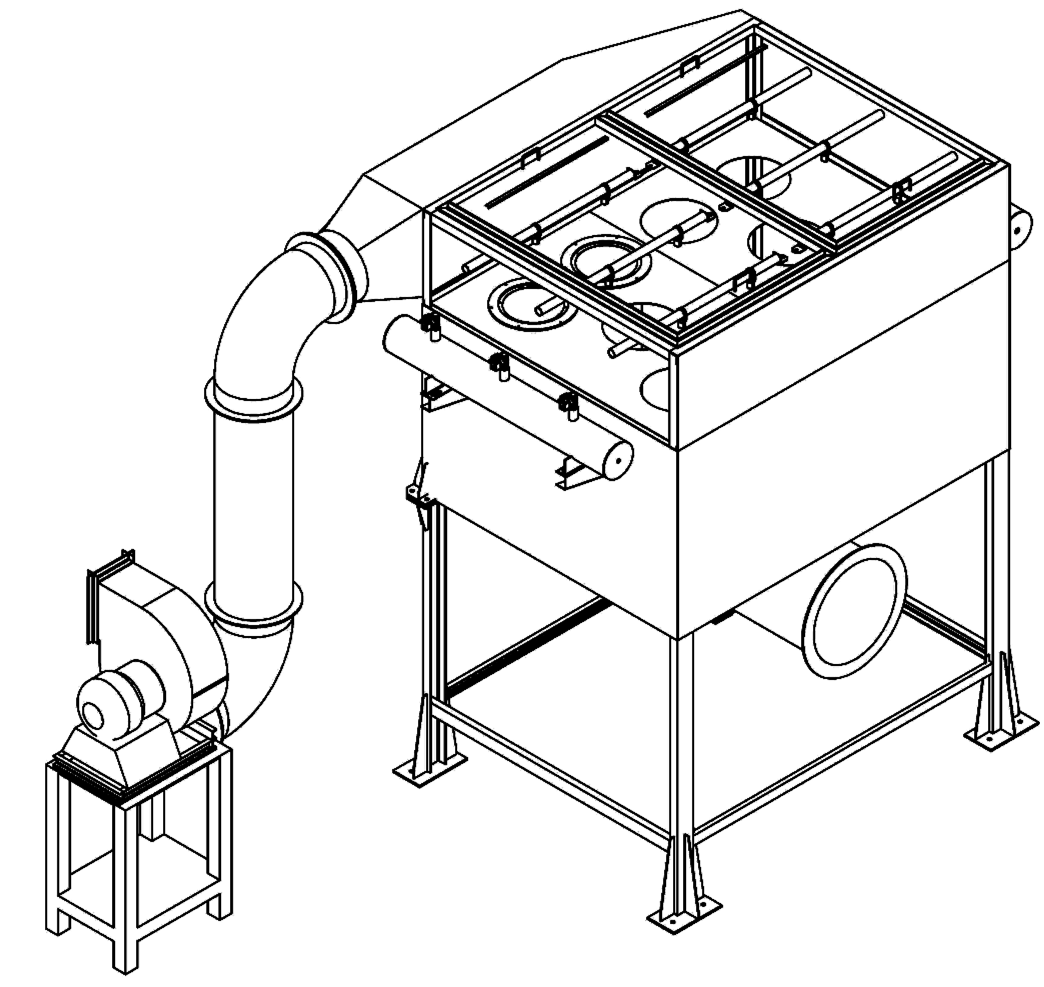

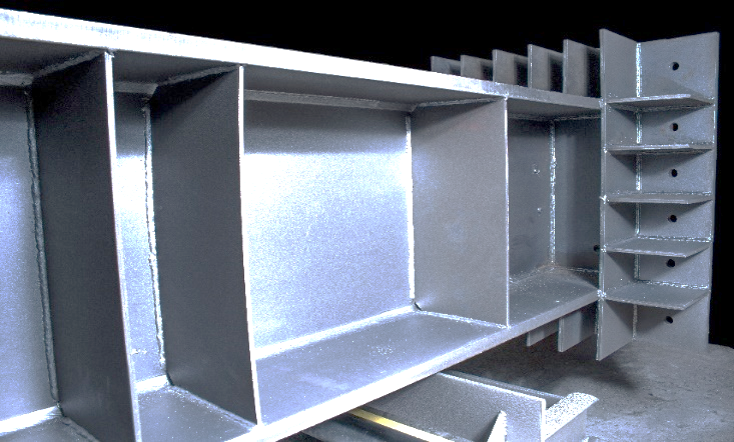

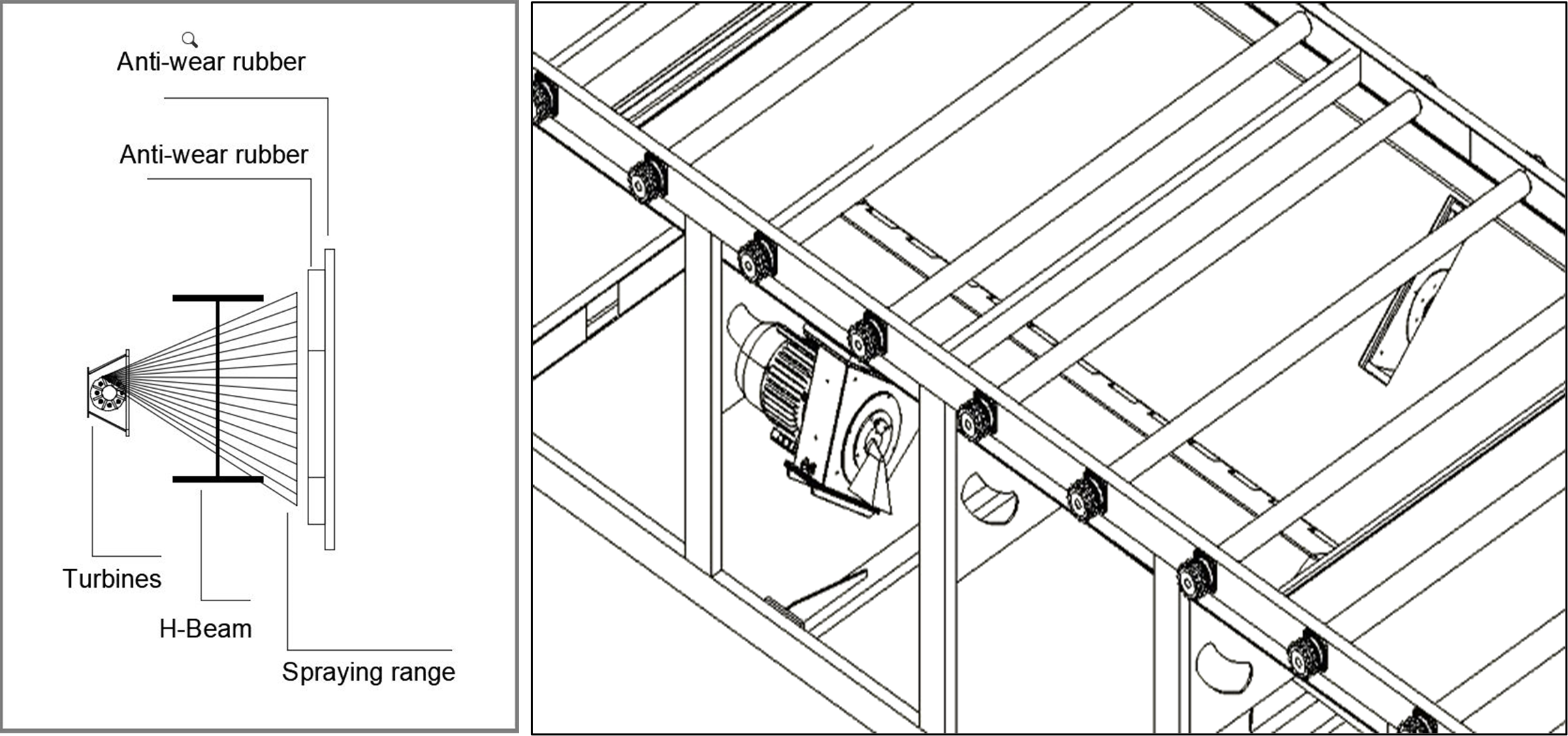

Blast Cabinet

Shot-throwing turbines are installed on the cab and start firing at the right angle when the workpiece is open. Shot angle and shot distance are very important in the design of this machine.

The internal body of the shot blast cabin has anti-wear rubber Anti-wear tires are among the most widely used industrial tires in the industry Due to the high resistance of these tires to abrasion and scratches, sharp objects such as sharp metal parts such as shot and grit are used in the inner body of the shot blast cabin.

These tires can withstand temperatures from -30 to + 75 degrees Celsius and do not lose their properties. This sheet also has 120mm³ abrasion resistance.

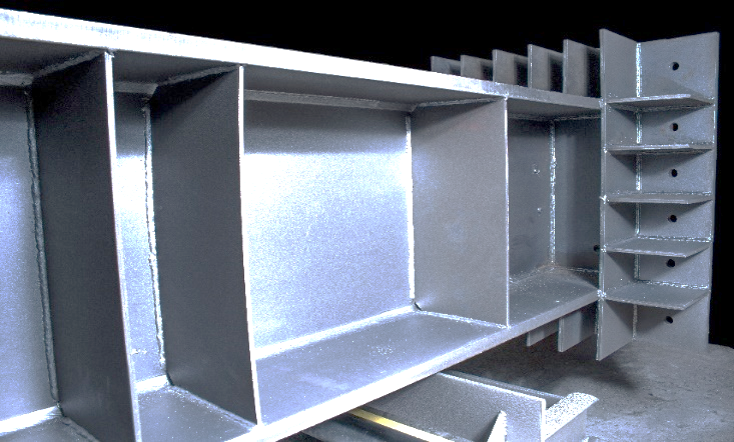

Sheet rollers are equipped with anti-wear cast iron pipe Anti-wear cast iron pipes are produced by casting method.

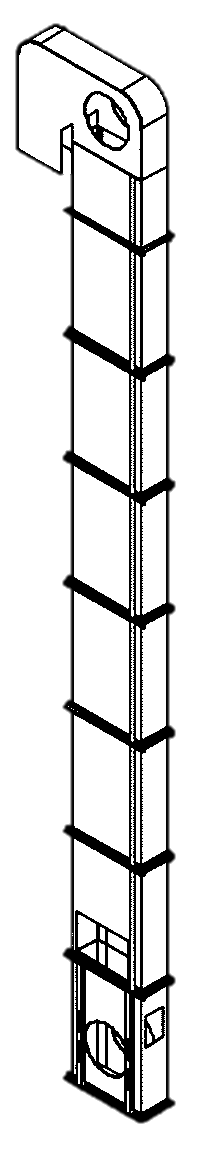

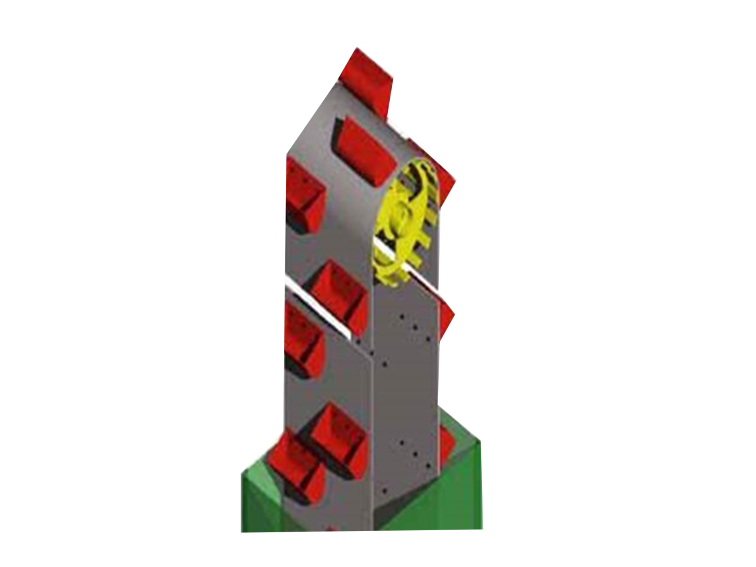

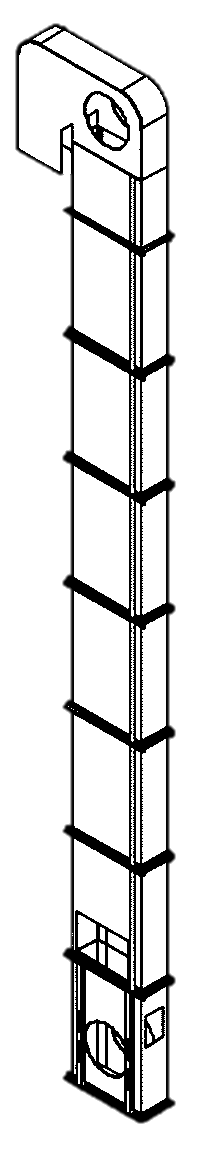

Shot Elevator

KARA Co. manufactures and supplies rubber bucket belts for steel shot elevators in various sizes, thickness and features according to the requirements and demands of the work.

We manufacture our belts according to DIN 22102 conveyor belt standards:

- Rubber.

- Types of textile: EP Polyester, Polyamide.

- Strength member or Carcass of one, two, three or more fabrics (breaking loads).

- Tear resistant, low stretch characteristics and resistance to abrasion of the cover.

- Diameter of drum recommended: 250 to 1250 mm, according to number of plies.

Quality and Properties of Elevator Belts:

- Fire retardant, oil resistant, antistatic and complies with ATEX standard.

- Highly resistant to oils.

- Highly resistant to abrasion and temperature (150 ºC).

- Highly resistant to abrasion and high temperatures (200 ºC).

- Highly resistant to abrasion

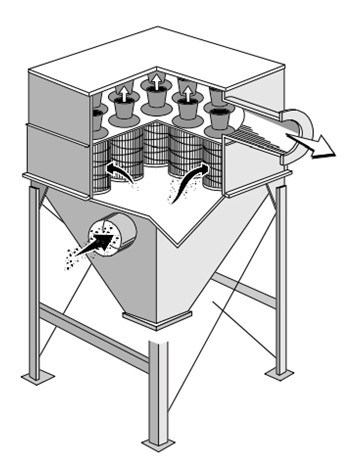

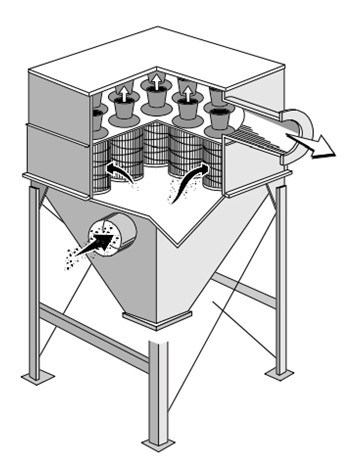

Dust Collector Systems

Dust collectors (which includes the dust filter outlet of the device) are part of the standard range of dust collectors. The dust collector set designed by Kara Company has an exceptional function in collecting dust during shot blasting of sheets and sections. Dust collectors in this collection have a shot blast for use in facilitating air circulation and ventilation of the cabinet. These machines are equipped with cartridge filters to collect dust that must be replaced over time for better performance.

- Modular design for flexibility, each module accommodates up to 5,000 cfm

- Number of Filters: 10 set

- Number of Valves: 10

- Vertical cartridge design for efficient pulsing of dust and efficient cleaning.

- Heavy duty construction, 3g and 5 g steel.

- Easy access to filters to replace.

- Automatic timer control filter cleaning.

- Energy efficient premium fan motor.

- Complete set of high-performance filter cartridges.

Dust Collector Cartridge Filter Polyester

- Fiber Type: Polyester

- Construction: Filter Cartridge

- Media: 100% Polyester

- Weight: 8 Kgs

- Certification: ISO 9001

- Dimension (Ø1 x Ø2 x H): 480 x 380 x 1220

- Cartridge Installation: Vertical Lifting

- Filtration surface(m2): 13.0m2

- Usage: Dust Filter, Air Filter

- Applicable Temperature: 120°C

- Filtration Precision: 10 Micron

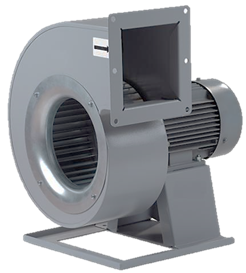

Dust Centrifugal Fan 15Kw

This fan is produced in two models of direct coupling. The inlet and outlet of these fans have a flange.

All impellers are balanced by the balancing machine model ZE300 made in Italy and all the fans are provided with a report test (balance certificate). All fans have a double chassis and are equipped with anti-vibration.

Engine power: 15 kw, Speed: 3000 rpm, Air flow max: 10000 m3/h, Noise level: 88 dB

The blasting angle can be set by means of an externally adjustable control cage. It serves to concentrate the blast directly at the Hot Spot (the area where the work pieces are optimally exposed to the Shot stream)

The blasting angle can be set by means of an externally adjustable control cage. It serves to concentrate the blast directly at the Hot Spot (the area where the work pieces are optimally exposed to the Shot stream)

Sheet rollers are equipped with anti-wear cast iron pipe Anti-wear cast iron pipes are produced by casting method.

Sheet rollers are equipped with anti-wear cast iron pipe Anti-wear cast iron pipes are produced by casting method.