Longitudinal Seam Welder:

Longitudinal

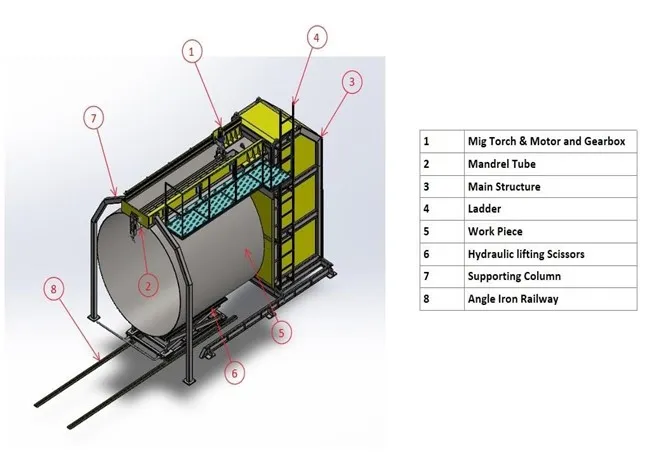

seam welding is a process in which a piece of sheet metal that is fully rolled is welded along the seam of its two ends. welding process could be either MIG_MAG or TIG depending to the customer order.

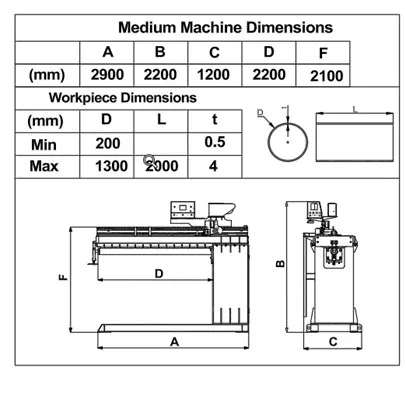

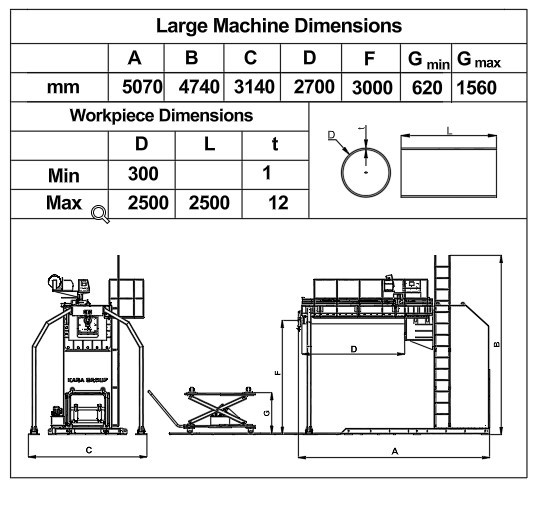

This process easily enables the joining of two flat plates of material together to form a cylinder. Longitudinal seam welding can be used on smooth plates, sheets, pipes, and tank sections to make cylindrical workpieces.Seam welder machines in KARA Group company are manufactured in three different sizes. From small size to medium and finally large size , the capacity of workpiece dimensions and weight increases.

Workpiece is completely fixed on seam welder machine by pneumatic clamping mechanism. Precise movement of welding torch along its longitudinal move via linear sliding guide and step motor guaranties high quality of welding joints.

Due to heavy weight of workpiece a hydraulic lifting scissors is used to easily lift and mount workpiece in large size

seam welder machine.

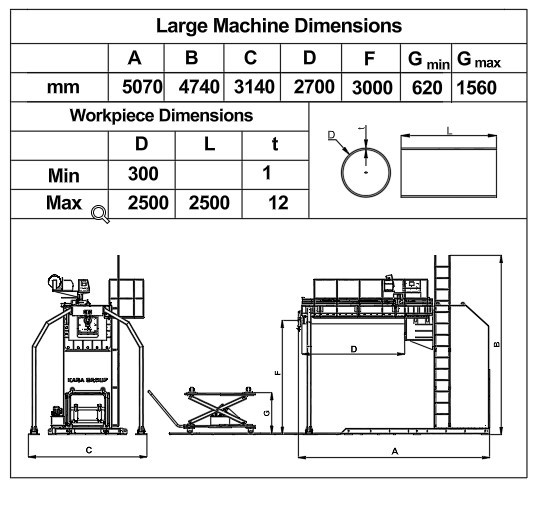

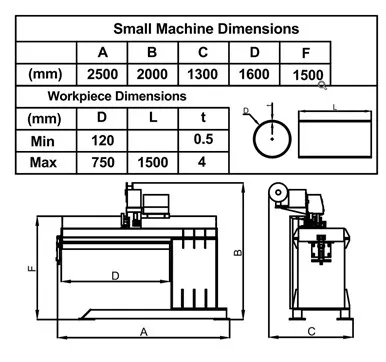

Overall Diemensions of small size Longitudinal Seam Welder

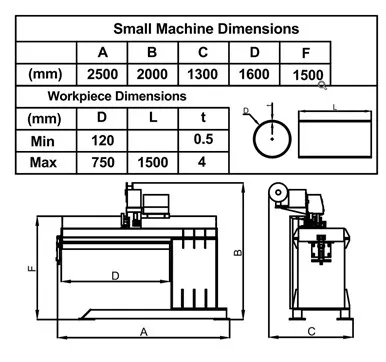

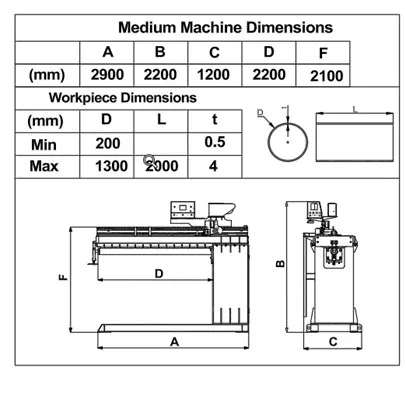

Overall Diemensions of medium size Longitudinal Seam Welder