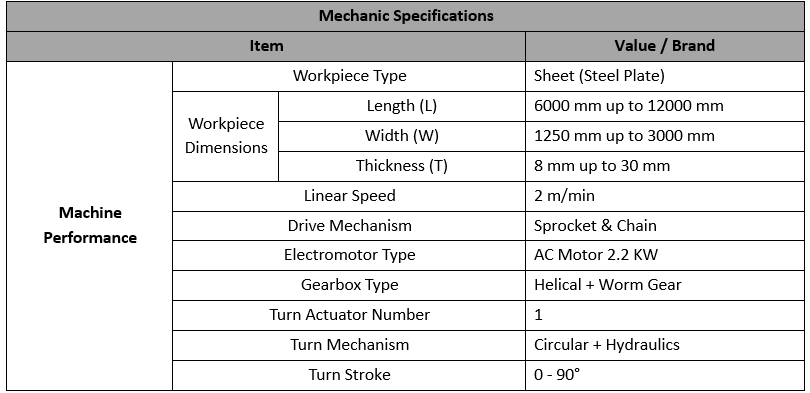

plate processing & shot blasting machine

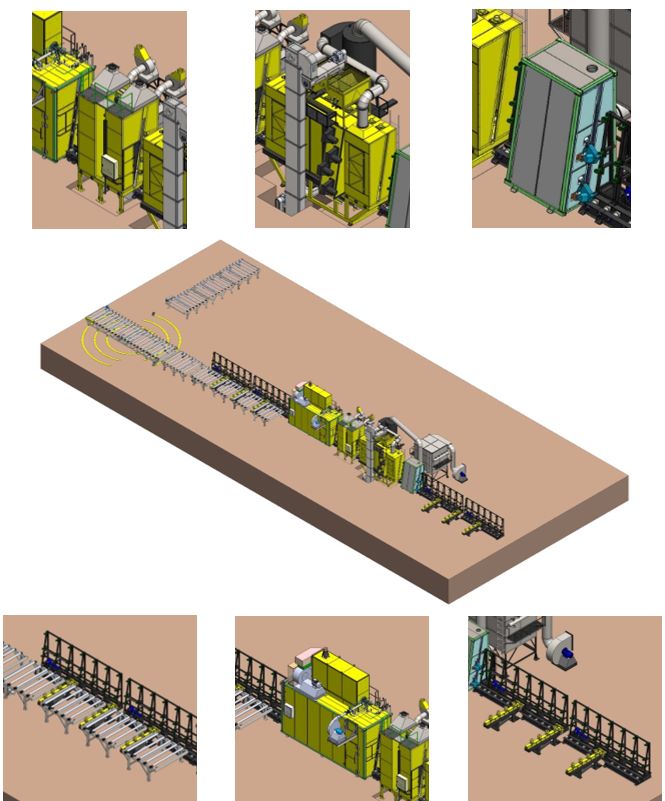

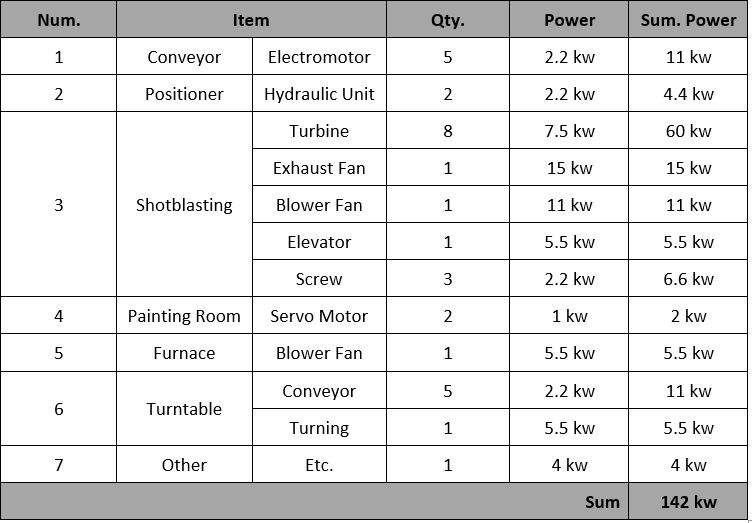

1.The main schematic

The set of these machines is used for

shot blasting and painting a steel sheet for the initial preparation of its warehouse. This line is approximately 64 meters long and 10 meters wide, which includes the primary sheet heater, shot blasting, coloring and sheet dryer. There is also a 22-meter-long rotary table transfer system (12 rotary tables and 10-meter fixed tables) in the continuation of this line

Line performance:

- First, the sheet changes position by the Hydraulic Positioner to rotate from horizontal to vertical to be placed on the Vertical Roller Conveyor.

- Now, the sheet moves into the Pre-Heat cabine before the shot blasting.

- After heating, the sheet is transferred into the shot blasting machine.

- The shot blasted sheet is transferred to the painting cabine.

- Then the painted sheet moves into the dryer.

- The dried sheet is moved to the end of the line and changed to horizontal position by the Hydraulic Positioner.

- All these operations are done continuously.

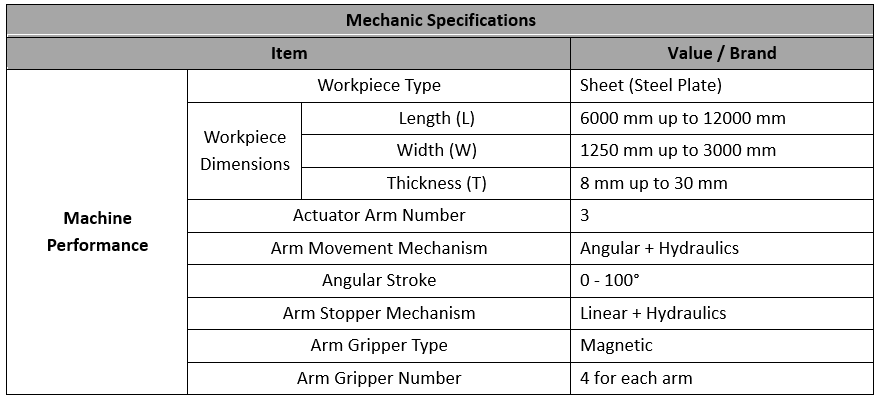

2. Hydraulic Positioner

The hydraulic positioner machine consists of three Actuator arms. This machine holds the sheet by using magnetic gripper. In the loading position, this machine changes the sheet from horizontal to vertical position, and in the unloading position, it changes the sheet from vertical to horizontal position. The model of one of the actuator arms is shown in the image

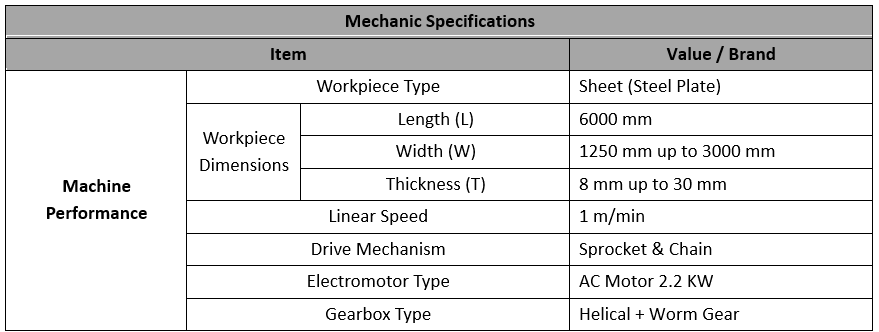

3.Vertical Roller Conveyor

The vertical conveyor machine consists of a truss structure. This structure uses vertical casters to control the weight of the sheet and horizontal cone wheel to move the sheet along the line. The model of one of the vertical conveyor machine is shown in the figure.

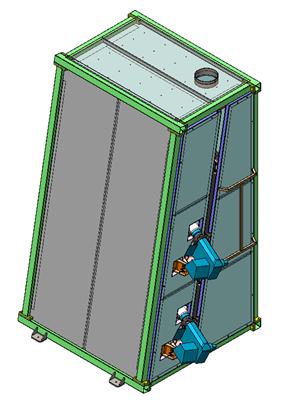

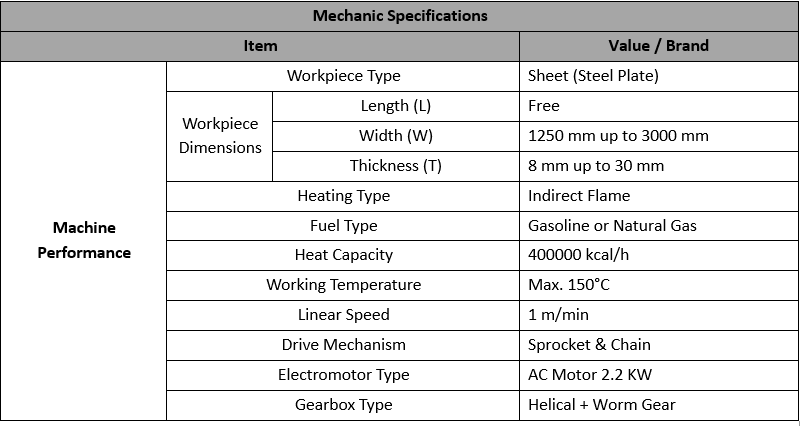

4. Pre-Heat

The preheat furnace is used for initial heating of the sheet before the blasting process. This furnace can heat the sheet up to 60 degrees Celsius. Its function is as a direct flame on the surface of the sheet. Its schematic is shown in the figure.

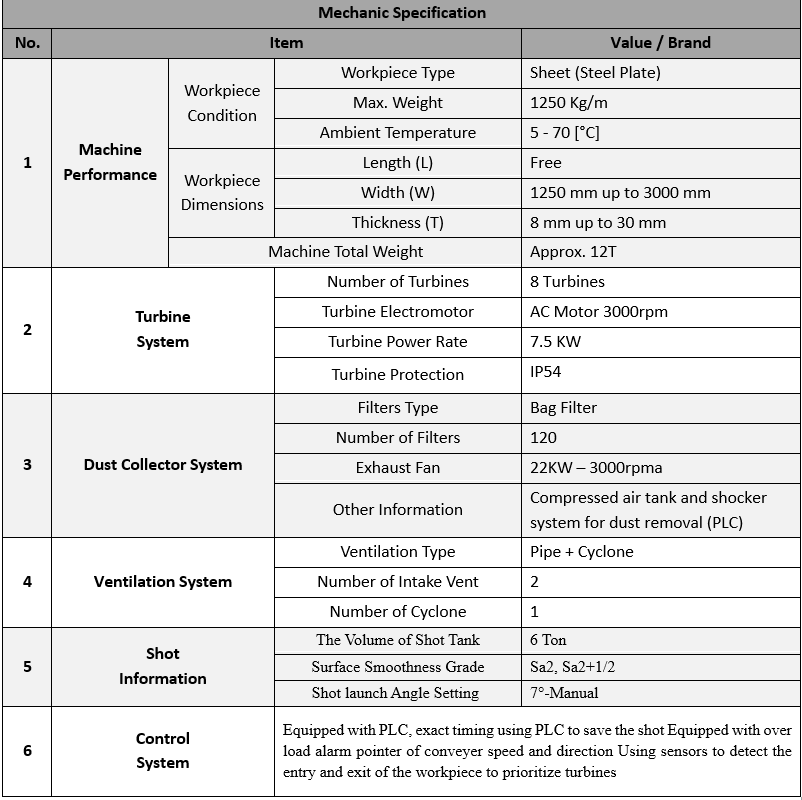

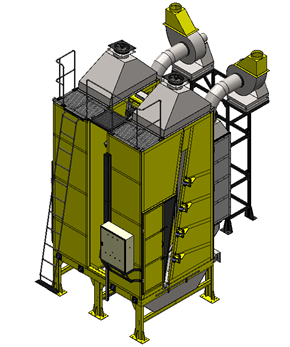

5. Shot Blasting

Vertical Steel Plate Shot Blasting Machine is a machine with different components. This machine contains several main sets and sub sets that must be assembled together. The main Sets are as follows:

- Shot Room

- Conveyors

- Elevator & Screws & Shot Tank

- Cyclone

- Dust Collector

- Pipes

- Electrical Boxes & Ducts

The Steel Plate Shot Blasting Machine allows wide working range for Sheet from diameters 0 to 3000 mm. Advanced design and top quality components enable fast and efficient blasting with top quality results. The most important feature and advantage is its user friendly software which enables quick understanding and efficient use of this machine after a short training. In the figure, all the components of a vertical sheet shot blasting machine assembled together are shown.

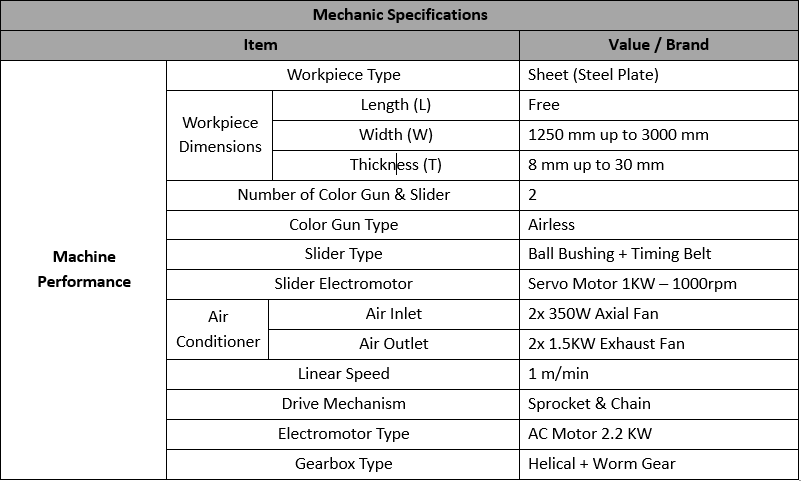

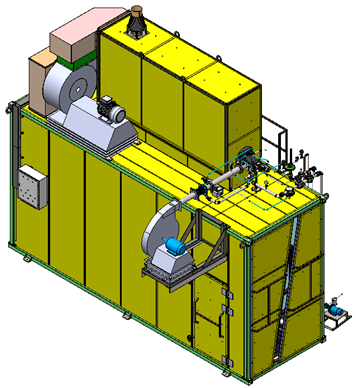

6. Painting Room

The Steel Plate Painting Machine is used to paint both sides of a sheet. The type of paint is shop primer. In this machine, the coloring operation is done by using two guns that move simultaneously and parallel on each side of the sheet.

7. Furnace

The main furnace is used to dry the sheet after the painting process. This furnace increases the temperature up to 150 degrees Celsius. The function of this furnace is indirect flame.

8. Turn Table & Horizontal Roller Conveyor

Vertical The Turn table and horizontal Roller Conveyor line includes a series of tables with metal structures on which horizontal rollers are installed. The task of this line is to transfer the sheets to the next hall after completing all the processes. The length of this line can be different

depending on the type of delivery hall.