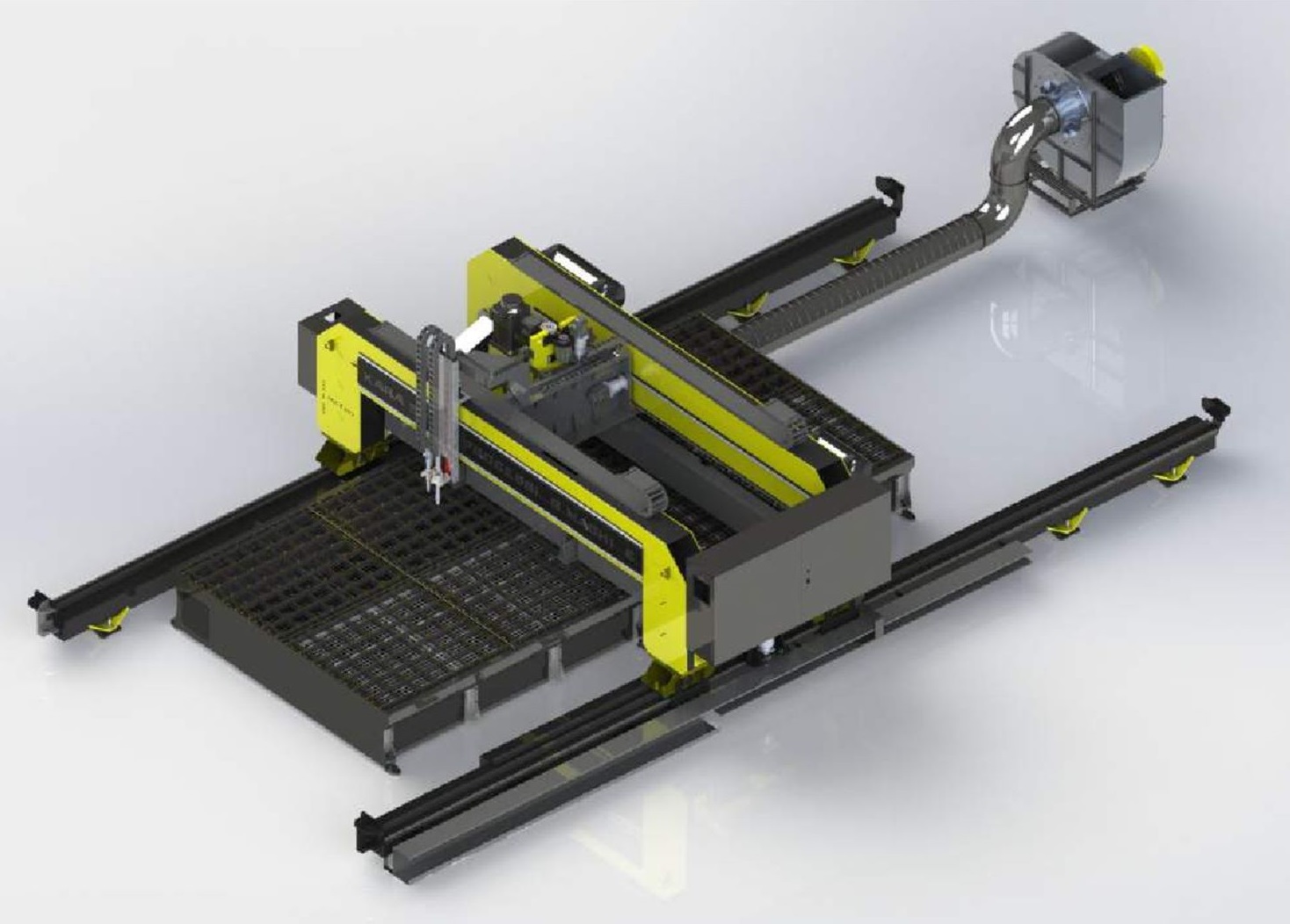

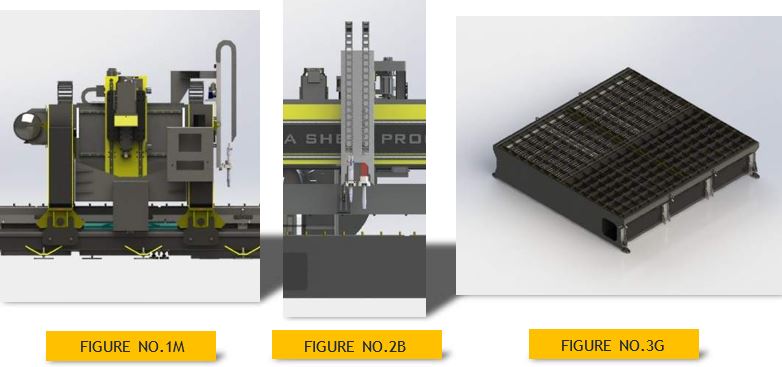

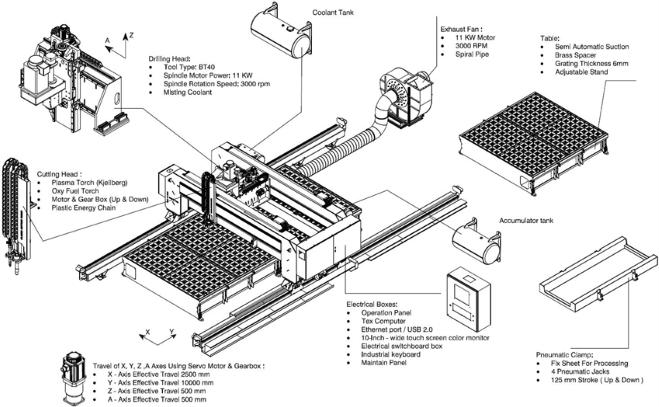

Main Technical Specifications (Cutting Part)

Main Technical Specifications (Drilling Part)

Main Technical Specifications (Tables)

Kara Sazeh Welding and Cutting Industrial Company was established at 1989 in Markazi Province, in order to achieve industrial self-sufficiency and according to the country’s need for welding and cutting machines. As the only manufacturer of the complete line of automatic equipment for the construction of steel structures and the largest producer of machinery and welding and cutting equipment in Iran and the Middle East.

U. 3, 3th FLR, No. 28, NajmAbadi Sq, Shams Tabrizi St, Mirdamad Blvd, Tehran, Iran, Zip Code: 1919714389

HajiAbad, 6th Kilometer outside in Arak-Qom Highway, Arak, Markazi Province, Iran

© 2024 KARA Welding & Cutting Ind. Mfg. Co. All rights reserved.