If you’re looking for a welding method that delivers clean results, high precision, and minimal defects, plasma welding is definitely worth your attention. The key difference lies in how the arc is formed: instead of spreading out, the electric arc is forced through a very narrow nozzle, turning into a focused plasma jet that strikes the metal with pinpoint accuracy. This high level of concentration allows heat to be delivered exactly where it’s needed, giving the operator much better control over penetration—especially when working with thin sheets or delicate components. In this process, plasma plays the leading role. It’s an ionized gas that stabilizes the arc while carrying enough energy to melt the metal efficiently.

Because of this exceptional precision and consistency, plasma welding is widely used in high-end industrial applications such as medical equipment, aerospace components, and stainless steel fabrication, where weld quality and uniformity are absolutely critical.

Plasma welding is an advanced arc welding process designed for applications where accuracy and control are non-negotiable. Structurally, it shares similarities with TIG welding, but there’s one crucial distinction that sets it apart: the electric arc is constricted inside a very fine nozzle, forming a narrow, high-energy plasma column before reaching the workpiece. This is why plasma welding is often described as a more precise evolution of TIG. Inside the nozzle, the shielding gas is exposed to intense heat and becomes ionized, entering the plasma state—a form of gas with extremely high energy density.

This concentrated heat makes it easier to control the weld pool, achieve precise penetration, and produce a consistently uniform weld bead. These advantages become especially noticeable when welding thin materials or sensitive parts, where even small variations can affect the final quality.

In conventional welding processes, the arc tends to spread out. That means the heat is more dispersed, and controlling the weld pool becomes harder—especially on thin or sensitive materials. Plasma welding works differently. Here, the arc behaves like a hot needle, sharply focused and highly controlled.

The reason is simple: the plasma nozzle constricts the arc and prevents it from spreading. As a result:

In simple terms, if TIG welding is like painting with a brush, plasma welding is more like writing with a pen. The energy level is similar, but the focus is much tighter.

Plasma welding isn’t a one-size-fits-all process. Depending on material thickness and application, it’s typically used in three main modes. Let’s break them down.

This mode is used when the material is extremely thin—sometimes even thinner than what TIG welding can handle reliably. You’ll see micro plasma welding in medical components, ultra-thin sheets, and precision laboratory work. Control is exceptionally high, and the risk of burn-through is kept to an absolute minimum.

This is the most common plasma welding mode in industrial environments. It’s ideal for medium-thickness materials where both strength and surface quality matter. In many applications, it has replaced TIG welding because it offers better penetration and a noticeably cleaner weld appearance.

This is where plasma welding shows its real power. The arc becomes so concentrated and energetic that it creates a narrow opening—known as a “keyhole”—through the full thickness of the material. This allows the entire joint to be welded in a single pass. The method is excellent for thicker sections and significantly increases welding speed.

Micro Plasma | ultra-fine, precision work |

Normal Plasma | clean, industrial-grade welding |

Keyhole Plasma | deep penetration and high productivity |

In plasma welding, a tungsten electrode is housed inside the torch, positioned behind a very narrow nozzle. When the operator powers up the system, a small initial arc forms inside the torch itself—this is known as the pilot arc. The heat from this arc ionizes the gas, pushing it beyond its normal state and into the plasma phase.

This highly focused plasma stream exits the nozzle at high pressure, behaving much like the jet used in Plasma cutting, with the key difference being precise control for welding rather than separation. What’s the result? The metal melts exactly where the welder wants it to—no wandering heat, no guesswork. A separate shielding gas, usually argon, flows over the weld pool afterward to protect it from air and oxygen, preventing contamination.

Put simply, the plasma welding process works like this:

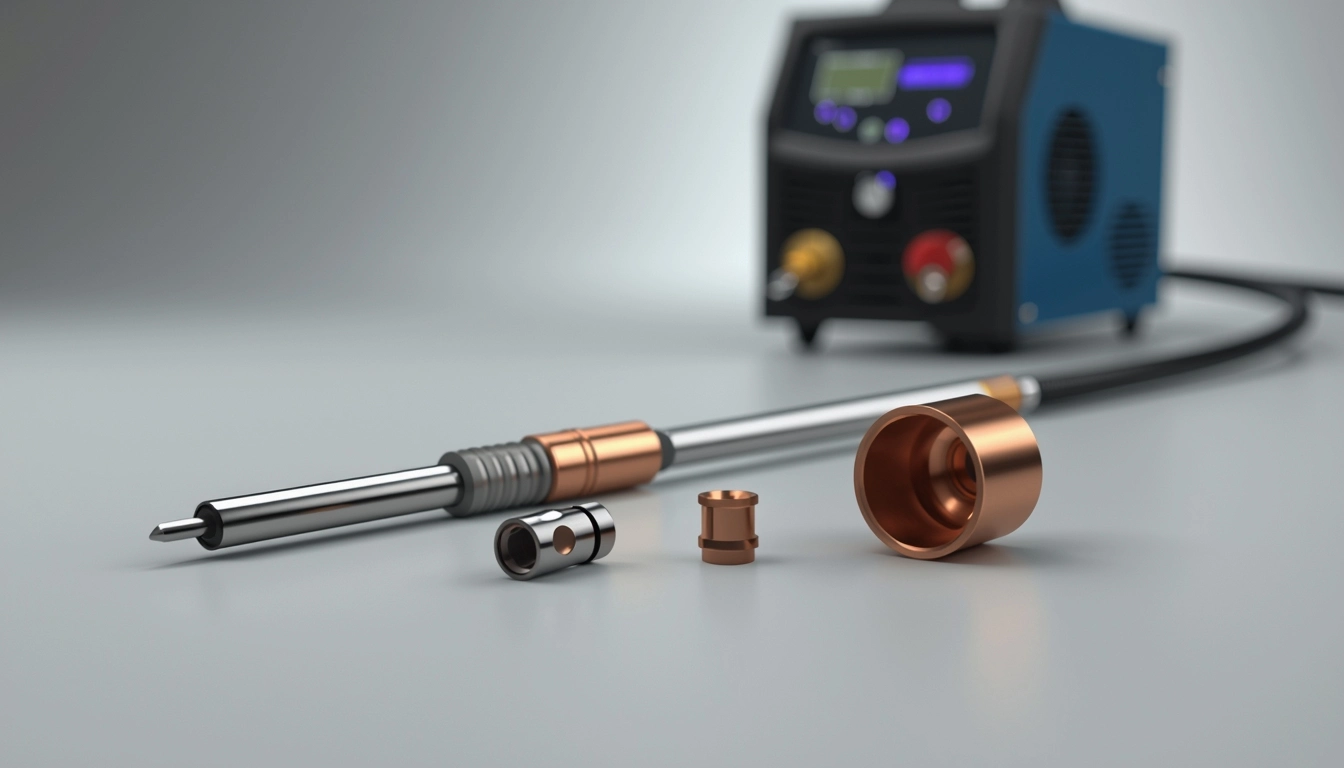

Despite how advanced it sounds, plasma welding isn’t built on mysterious or exotic equipment. It’s more like familiar tools, just arranged one level more professionally. Let’s take a look at the main components that give plasma welding its edge.

This is the heart of the system. Inside the torch sits the tungsten electrode along with a narrow nozzle that constricts the arc. The result is a plasma flame that behaves like a hot, ultra-precise needle.

Its job is to generate the arc, but it doesn’t melt or get consumed. Because it’s recessed behind the nozzle, it operates more stably than in conventional TIG welding.

This small part plays a huge role. Gas is forced through it at high pressure, where it becomes plasma. The more precise the nozzle opening, the cleaner and more controlled the weld.

The power source must deliver extremely stable and finely adjustable current—something only high-quality welding and cutting power supplies can provide, especially when working with thin or sensitive materials.

Argon is typically used. One gas forms the plasma arc, while a second gas shields the molten weld pool from atmospheric contamination.

Plasma welding generates intense heat, so the torch must be continuously cooled. Most systems use water cooling to keep temperatures under control and protect the equipment.

Like any welding process, plasma welding has its strengths and limitations. Knowing both helps you decide whether it’s the right tool for your application.

Plasma welding isn’t meant to be a universal solution—it’s a precision industrial tool. Wherever accuracy, heat control, and weld quality matter more than sheer speed, plasma welding stands out.

Thanks to its stable arc and controlled penetration, plasma welding is ideal for aircraft structures, blades, and thin critical joints—where even a millimeter of error can cause serious problems.

Medical tools, small tanks, stainless tubing, and hygienic components require extreme precision. Plasma welding delivers clean, reliable joints with minimal distortion.

Because of its consistency and cleanliness, plasma welding is widely used for tanks and pipelines where hygiene, smooth surfaces, and weld appearance are critical.

When manufacturers need to weld hundreds or thousands of identical components, plasma welding’s automation capability ensures consistent quality—unlike TIG, which relies heavily on operator skill.

For certain medium-thickness materials, plasma welding can achieve full penetration in a single pass, saving time and filler material compared to multi-pass methods.