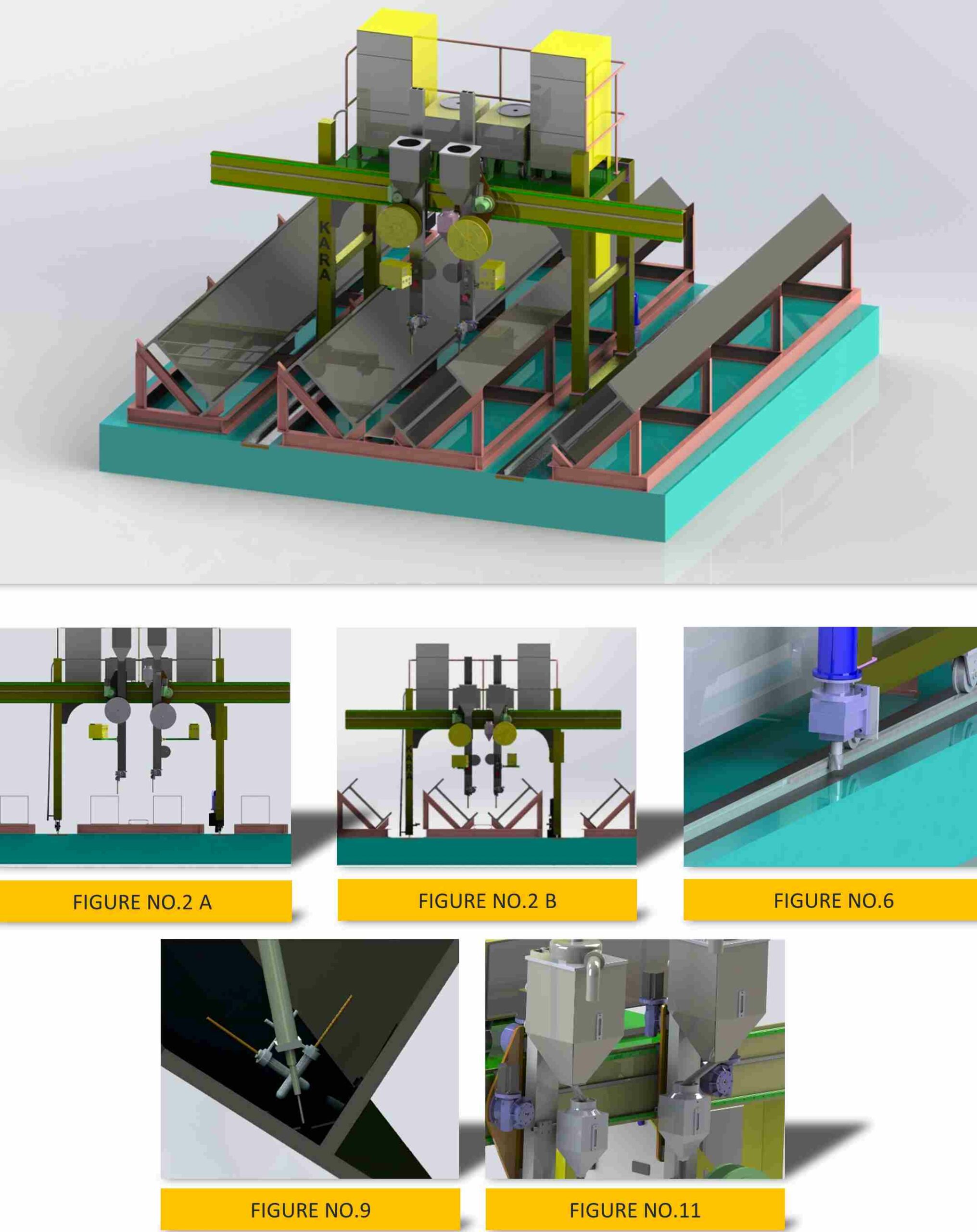

Main Technical Specifications

| Subject | Descriptions |

|---|---|

| H-Beam's welding area | Min: 200 mm – Max: 1500 mm - inside & outside |

| Box welding area | Min: 350 mm – Max: 1500 mm - inside & outside |

| H-Beam & Box Length | Up to 12000 mm |

| Machine's Linear movement speed | 250 ~ 1800 mm/min |

| Machine's control system | PLC - Fatek |

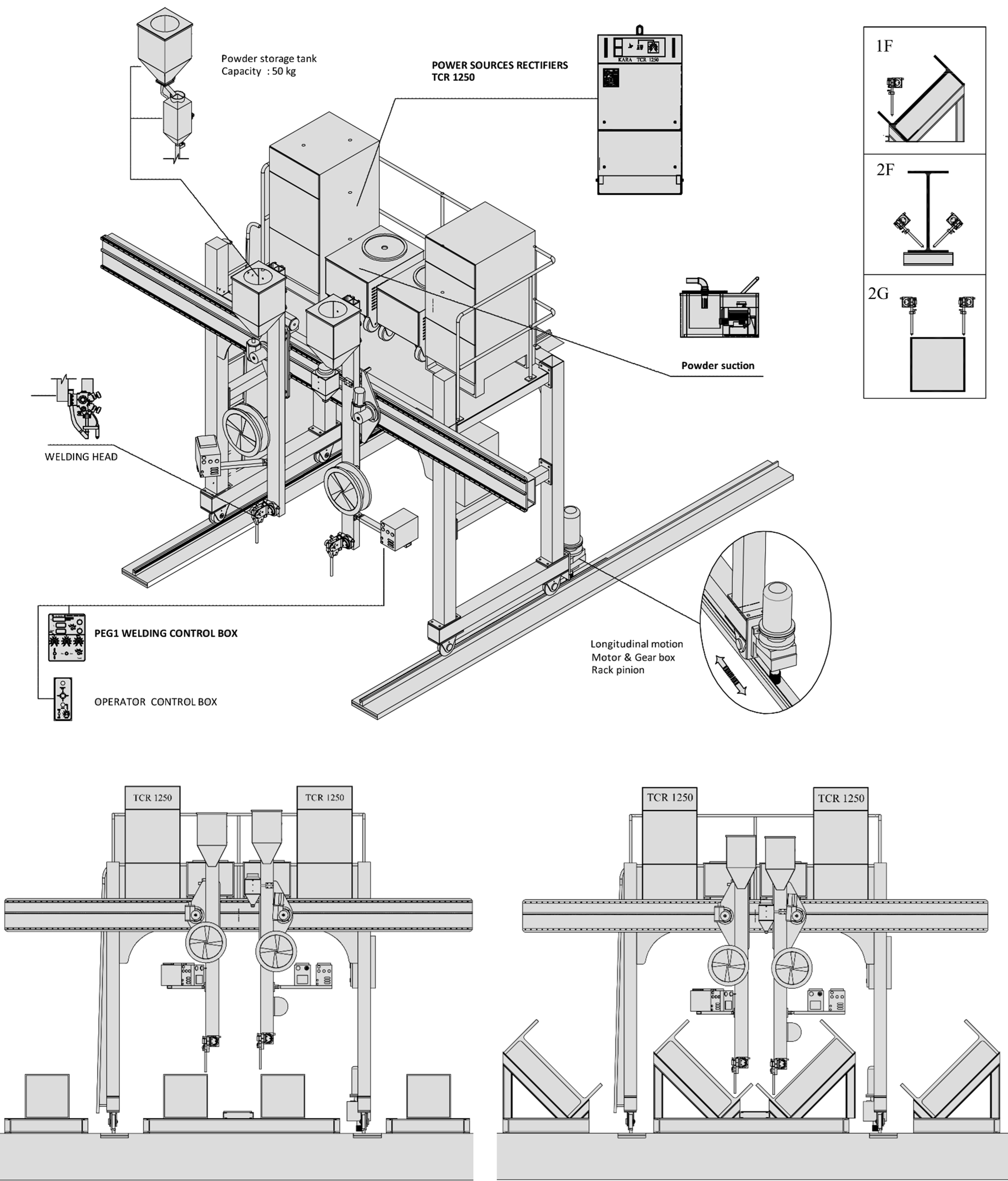

| Machine's linear movement system | Motor & Gearbox + rack pinion for 2 sides |

| Panel's degree of protection | IP 52 |

| Machine's Electric Power Consumption | Nominal Current @ Max. loud: 380v – 50Hz 3ph – 220A |

| Welding nozzles guidance system | 2 Automatic Proximity sensor for each side |

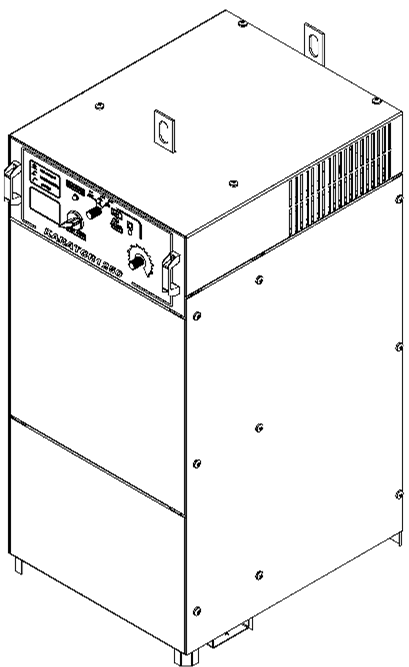

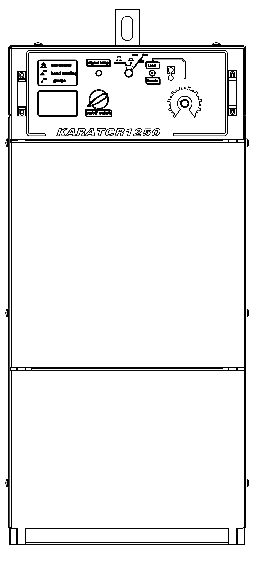

| Welding's power supply | KARA TCR 1250 A - 2 Set |

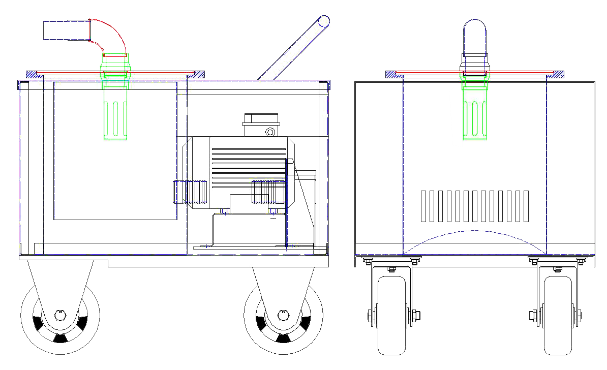

| Welding powder collection system | KARA Suction, 2 Set |

| Welding powder tank capacity | 50 liters for each head |

| Capacity of welding wire pulleys | 35 Kg for Each Head |

| Power of welding wires | Wire 2.4 mm ~ 5 mm |

| Overall Machine's Dimension (mm) | W: 5000 mm, H: 3750 mm, L :1600 mm |

| Overall Machine's Weight (kg) | 2800 |

KARA TCR 1250A Technical Specifications

KARA Suction Unit

Kara Sazeh Welding and Cutting Industrial Company was established at 1989 in Markazi Province, in order to achieve industrial self-sufficiency and according to the country’s need for welding and cutting machines. As the only manufacturer of the complete line of automatic equipment for the construction of steel structures and the largest producer of machinery and welding and cutting equipment in Iran and the Middle East.

U. 3, 3th FLR, No. 28, NajmAbadi Sq, Shams Tabrizi St, Mirdamad Blvd, Tehran, Iran, Zip Code: 1919714389

HajiAbad, 6th Kilometer outside in Arak-Qom Highway, Arak, Markazi Province, Iran

© 2024 KARA Welding & Cutting Ind. Mfg. Co. All rights reserved.